ENERGY

ENERGY

Natural resources are classified into two main categories: renewable resources and non-renewable resources. These classifications are based on their availability, rate of replenishment, and environmental impact.

1. Renewable Resources

Definition:

Renewable resources are natural resources that can be replenished naturally over time or can be reused without depleting them permanently. These resources are considered sustainable as they can be continuously available for future generations if managed responsibly.

Examples of Renewable Resources:

- Air – A freely available resource necessary for life and wind energy.

- Water – Essential for drinking, agriculture, and energy production (hydropower).

- Wind – A source of clean energy used for wind turbines and power generation.

- Sunlight – A limitless source of solar energy, used in solar panels to generate electricity.

- Biomass – Organic material (like wood, crops, and waste) used as a renewable source of energy.

- Geothermal Energy – Heat from the Earth’s interior, used for heating and power generation.

Key Features of Renewable Resources:

✅ Sustainability: These resources can be replenished naturally within a short period.

✅ Eco-Friendly: They do not cause significant harm to the environment when used properly.

✅ Unlimited Availability: Many of these resources, such as solar and wind energy, are virtually inexhaustible.

✅ Lower Pollution Levels: Using renewable energy sources helps reduce carbon emissions and environmental degradation.

✅ Renewal Rate: The rate of replenishment is higher than or equal to the rate of consumption, making them a long-term energy solution.

2. Non-Renewable Resources

Definition:

Non-renewable resources are natural resources that cannot be replenished within a human lifespan once they are depleted. They are typically formed over millions of years and are exhaustible, meaning their availability diminishes as they are used. These resources are a primary cause of environmental pollution and climate change.

Examples of Non-Renewable Resources:

- Fossil Fuels: Includes coal, petroleum (crude oil), and natural gas. These are major sources of energy but contribute to pollution and climate change.

- LPG (Liquefied Petroleum Gas): A widely used cooking fuel but derived from non-renewable fossil sources.

- Metals and Minerals: Resources like iron, copper, aluminum, and gold, which take millions of years to form and are mined from the Earth.

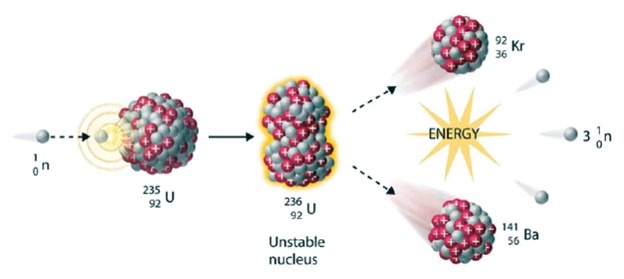

- Nuclear Energy: While uranium is used to generate nuclear power, it is a finite resource and is not naturally replenished at a fast rate.

Key Features of Non-Renewable Resources:

❌ Exhaustibility: Once depleted, these resources take millions of years to replenish.

❌ Pollution: The extraction and burning of fossil fuels release harmful emissions that contribute to global warming.

❌ Limited Availability: The consumption rate of these resources is much faster than their formation rate.

❌ Dependency Risk: Many countries depend heavily on fossil fuels, leading to economic and geopolitical tensions.

❌ High Environmental Impact: Mining, drilling, and extraction of non-renewable resources cause land degradation, habitat destruction, and water pollution.

Comparison Table: Renewable vs. Non-Renewable Resources

Feature | Renewable Resources 🌍 | Non-Renewable Resources ⚠️ |

Definition | Resources that can be naturally replenished or reused over time. | Resources that cannot be replenished within a human lifespan once exhausted. |

Examples | Sunlight, wind, water, biomass, geothermal energy. | Fossil fuels, metals, minerals, LPG, uranium. |

Sustainability | Sustainable and environmentally friendly. | Exhaustible and cause environmental degradation. |

Availability | Available in unlimited or naturally replenishing amounts. | Limited and takes millions of years to form. |

Environmental Impact | Minimal or no pollution, helps reduce carbon footprint. | Causes high pollution levels, contributes to climate change. |

Renewal Rate | Faster than or equal to consumption rate. | Slower than consumption rate, leading to depletion. |

Energy Production | Used in clean energy technologies (solar panels, wind turbines). | Used for conventional energy production (oil, coal, gas). |

Why Should We Promote the Use of Renewable Resources?

The excessive dependence on non-renewable resources has led to global climate change, air pollution, resource depletion, and environmental degradation. Switching to renewable resources can provide long-term sustainability, reduce dependence on fossil fuels, and promote a cleaner and healthier planet.

Advantages of Renewable Resources Over Non-Renewable Resources:

✅ Eco-Friendly Energy Production – Renewable sources produce little to no emissions, unlike fossil fuels.

✅ Sustainable Economic Growth – Investing in renewable energy creates jobs and boosts economies.

✅ Reduces Carbon Footprint – Helps in combating global warming and climate change.

✅ Energy Security – Reduces reliance on imported fuels and ensures energy independence.

✅ Preserves Natural Resources – Helps conserve forests, wildlife, and ecosystems from excessive mining and drilling activities.

Both renewable and non-renewable resources play a crucial role in human development and technological advancement. However, due to the depleting nature of non-renewable resources and their negative impact on the environment, there is an urgent need to shift towards sustainable alternatives. The adoption of solar, wind, hydro, and other renewable energies will help in achieving a greener and more sustainable future.

By promoting the responsible use of natural resources and advancing clean energy solutions, we can ensure a better environment for future generations while maintaining economic growth and energy security.

NON-RENEWABLE (CONVENTIONAL) ENERGY RESOURCES

Non-renewable energy resources are defined as those that cannot be regenerated or require an extensive period to form. These resources are limited in availability and encompass fossil fuels such as coal, oil, and natural gas. Additionally, they include other variants like asphalt, bioasphalt, liquefied petroleum gas (LPG), piped natural gas (PNG), compressed natural gas (CNG), liquefied natural gas (LNG), and various types of natural gas, including sweet and sour gas.

What is Coal?

Coal is a solid fossil fuel formed from decayed plant matter that has been compressed and heated over millions of years. It is rich in carbon and serves as a primary energy source for electricity generation, industrial processes, and metallurgy.

Coal is one of the most widely used energy sources in the world and plays a crucial role in the economic and industrial growth of many nations. In India, coal contributes approximately 55% of the country’s energy needs, making it a critical resource for power generation and infrastructure development.

Formation of Coal

Coal formation, known as coalification, is a geological process that takes place over millions of years. It occurs through the decomposition and compression of ancient plant material buried under sedimentary layers. The process involves:

- Accumulation of Plant Material – Dead plant matter accumulates in swamps and peat bogs.

- Burial & Compression – Over time, layers of sediment cover the plant material, exerting pressure and heat.

- Carbonization – The organic material undergoes chemical and physical changes, gradually converting into different coal types with increasing carbon content.

Uses of Coal

Coal is a versatile energy source used in multiple industries:

- Electricity Generation: Coal-fired power plants generate a significant share of global electricity by burning coal to produce steam, which drives turbines.

- Industrial Use: Essential for cement, steel, and chemical production due to its high heat generation capacity.

- Transportation: Historically used to power steam locomotives, though modern transportation has shifted to petroleum-based fuels.

- Synthetic Fuels & Chemicals: Used in the production of coal gas, coke, fertilizers, and synthetic oil.

Types of Coal (Based on Carbon Content & Heat Value)

Coal is classified into four main types based on its carbon content, energy efficiency, and level of metamorphism:

Type of Coal | Carbon Content (%) | Moisture & Volatility | Energy Efficiency (Heat Output) | Usage |

Anthracite (Highest Quality) | 85-98% | Very Low Moisture, High Carbon | Highest Calorific Value (8000+ kcal/kg) | Used in domestic heating, metallurgical processes, and power generation |

Bituminous (Most Common) | 45-85% | Moderate Moisture, High Volatility | High Calorific Value (5000-7000 kcal/kg) | Used in power plants, steel-making (coke production), and cement industries |

Sub-Bituminous | 35-45% | Higher Moisture, Lower Carbon | Medium Calorific Value (3000-5000 kcal/kg) | Used for electricity generation due to its lower sulfur content |

Lignite (Lowest Quality) | 25-35% | High Moisture, Low Carbon | Lowest Calorific Value (2000-3000 kcal/kg) | Used in power plants but produces more emissions |

Key Differences:

- Anthracite has the highest carbon content and burns cleaner with less smoke.

- Bituminous coal is the most commonly used due to its high energy content.

- Lignite coal, though the least efficient, is abundant and cheap, making it useful for electricity production.

Advantages of Coal

✔ Abundant & Widely Available – One of the most plentiful energy sources in many countries.

✔ Reliable Energy Source – Provides continuous power supply, unlike some renewable sources.

✔ High Energy Content – Efficient for large-scale industrial use and power generation.

✔ Economic Importance – Supports millions of jobs in the mining and energy industries.

Disadvantages of Coal & Environmental Impact

❌ Air Pollution – Burning coal releases carbon dioxide (CO₂), sulfur dioxide (SO₂), and nitrogen oxides (NOₓ), leading to global warming and acid rain.

❌ Deforestation & Land Degradation – Coal mining destroys ecosystems, forests, and wildlife habitats.

❌ Water Pollution – Runoff from coal mining contaminates rivers and groundwater with toxic heavy metals.

❌ Health Hazards – Coal mining exposes workers to lung diseases like pneumoconiosis (black lung disease).

The Future of Coal: Towards Sustainable Alternatives

With growing concerns about climate change and air pollution, many countries are reducing their dependence on coal and investing in renewable energy sources such as solar, wind, and hydroelectric power.

- Clean Coal Technologies (CCT): Innovations such as carbon capture and storage (CCS) and coal gasification aim to make coal use more environmentally friendly.

- Transition to Green Energy: Governments and industries are shifting towards sustainable energy to reduce greenhouse gas emissions.

Coal has been a crucial energy resource for centuries, supporting industrialization, economic growth, and energy production worldwide. However, due to its environmental impact, the world is gradually transitioning to cleaner, renewable alternatives. As technologies improve, coal use is expected to become more sustainable while reducing harmful emissions.

Coke:

What is Coke?

Coke is a tough, porous, and black substance that is an almost pure form of carbon. It is derived from coal through a process called coking or destructive distillation. Due to its high carbon content and low impurities, coke plays a vital role in industrial applications, especially in steel manufacturing and metal extraction.

Coke is lightweight, strong, and highly resistant to heat, making it an ideal fuel and a reducing agent in various metallurgical and chemical processes. It burns at very high temperatures with minimal smoke and is widely used in blast furnaces for metal refining.

How is Coke Formed? (Coking Process)

Coke is produced by heating coal at high temperatures in an oxygen-free environment over an extended period. This process, known as coking or destructive distillation, removes volatile components such as water, coal tar, coal gas, and other impurities, leaving behind pure carbon in the form of coke.

Steps in the Coking Process:

- Selection of Coal: Bituminous coal, which has a high carbon content and low sulfur content, is primarily used for coke production.

- Heating in Coke Ovens: Coal is heated in large industrial ovens at temperatures ranging from 1000°C to 1100°C without oxygen.

- Volatile Removal: Gases such as methane, hydrogen, carbon monoxide, and coal tar escape, leaving behind solid carbon residue (coke).

- Cooling & Processing: The coke is cooled using water or inert gases, then broken into smaller pieces for use in industries.

This process produces by-products such as coal tar, ammonia, benzene, and coal gas, which are used in chemical industries, pharmaceuticals, and fuel production.

Properties of Coke

✔ Porous & Lightweight – Allows gases to pass through, making it ideal for industrial use.

✔ High Carbon Content (~90-98%) – Enhances efficiency in metallurgical processes.

✔ High Thermal Resistance – Burns at very high temperatures without melting.

✔ Smokeless Combustion – Produces minimal pollution compared to raw coal.

✔ Chemically Stable – Does not react easily with other elements under normal conditions.

Uses of Coke

- Steel Production – Coke is an essential component in blast furnaces to extract iron from iron ore. It acts as a fuel and a reducing agent, helping convert iron ore into molten iron, which is later refined into steel.

- Metal Extraction (Smelting Process) – Used in extracting metals such as iron, lead, and zinc from their ores. The high-temperature combustion of coke removes oxygen from metal oxides, leaving behind pure metal.

- Fuel for Industrial Furnaces – Due to its high heat capacity, coke is used as fuel in cement kilns, glass production, and lime manufacturing.

- Production of Water Gas & Producer Gas – When coke reacts with steam or air, it produces gases like carbon monoxide and hydrogen, which are used as industrial fuels.

- By-Product Production – The coking process produces coal tar, coal gas, benzene, and ammonia, which are valuable for chemical, pharmaceutical, and fuel industries.

- Historical Use in Locomotives – In earlier times, coke was used as fuel in steam locomotives due to its high heat output and smokeless combustion.

Advantages of Coke Over Coal

- Higher Carbon Content – More efficient in metal refining processes.

- Burns at Higher Temperatures – Ideal for industrial furnaces and steel plants.

- Less Smoke & Pollution – More eco-friendly compared to coal.

- Stronger & More Durable – Can withstand high-pressure industrial environments.

Environmental Concerns & Sustainable Alternatives

Although coke is widely used in industry, its production and use contribute to air pollution, carbon emissions, and climate change. Sustainable alternatives, such as:

✔ Electric Arc Furnaces (EAFs) in steel production

✔ Hydrogen-based metal refining

✔ Biomass-based reducing agents

Are being explored to reduce dependence on coke and minimize environmental impact.

Coke is a high-carbon, porous fuel that is indispensable in steel manufacturing, metal extraction, and industrial heating. Its high thermal efficiency, durability, and chemical stability make it a preferred choice in metallurgy and industrial applications. However, with growing concerns about carbon emissions, industries are shifting towards cleaner and more sustainable alternatives to reduce environmental impact.

It is a tough, porous and black substance. It is an almost pure form of carbon. Coke is used in the manufacture of steel and in the extraction of many metals.

Coke is formed by heating coal in an oxygen-free atmosphere at high temperatures for a long time in a process called coking or destructive distillation.

Fly Ash

What is Fly Ash?

Fly ash is a fine, powdery residue produced by coal-fired power plants when coal is burned to generate electricity. It consists mainly of silicon dioxide (SiO₂), aluminum oxide (Al₂O₃), iron oxide (Fe₂O₃), and calcium oxide (CaO). These components make fly ash pozzolanic, meaning it can react with lime and water to form a cementitious compound, making it highly useful in construction.

Fly ash is collected from the flue gases of coal combustion using electrostatic precipitators or bag filters, preventing it from being released into the atmosphere and contributing to air pollution.

Sources of Fly Ash

Fly ash is primarily produced in thermal power plants, where coal is used as fuel. When coal burns at high temperatures, its non-combustible mineral components turn into fine ash particles that are carried away by the exhaust gases. These particles are captured before being released into the air, creating fly ash as a by-product.

Coal combustion generates two types of ash:

- Fly Ash – The finer, lighter particles collected from flue gases.

- Bottom Ash – Heavier particles that settle at the bottom of the furnace.

Uses of Fly Ash

1. Construction Industry: Cement & Concrete Production

- Fly Ash Bricks – Fly ash is used as a primary ingredient in making durable, lightweight, and eco-friendly bricks for building construction. These bricks require less energy to produce and provide better insulation than traditional clay bricks.

- Fly Ash Concrete – Fly ash is used as a partial replacement for Portland cement in concrete mixtures. It enhances strength, durability, and workability, reduces water consumption, and improves resistance to chemicals and temperature variations.

- Precast Concrete Products – Fly ash is widely used in pavements, pipes, blocks, and slabs, increasing their lifespan and strength.

- Road Construction & Embankments – Fly ash is mixed with soil and lime to improve road foundations and reduce settlement in highways, bridges, and embankments.

2. Agricultural & Environmental Applications

- Soil Amendment – Fly ash contains minerals that enhance soil structure and fertility, making it useful for land reclamation and agriculture. It helps neutralize acidic soils and improves moisture retention.

- Waste Management & Landfill Liner – Due to its low permeability, fly ash is used to line landfills and hazardous waste sites to prevent soil and water contamination.

- Water Treatment – Fly ash is used in wastewater treatment plants to remove heavy metals and toxic impurities from industrial effluents.

3. Industrial Applications

- Manufacturing of Tiles & Ceramics – Fly ash is incorporated into ceramic tiles, sanitary ware, and glass production due to its high silica content.

- Asphalt & Pavement Stabilization – When mixed with asphalt, fly ash improves the stability and longevity of roads and runways.

- Mine Fills & Reclamation – Fly ash is used to fill abandoned mines, preventing land subsidence and reducing environmental hazards.

Advantages of Using Fly Ash

✅ Eco-Friendly & Sustainable – Reduces the need for raw materials like clay, limestone, and sand, lowering carbon emissions and environmental impact.

✅ Cost-Effective – Fly ash-based materials reduce construction costs while improving durability.

✅ Enhances Strength & Durability – Fly ash concrete has higher resistance to corrosion, chemical attacks, and cracking.

✅ Reduces Water Usage – Improves the workability of concrete and requires less water for construction.

✅ Lightweight & Heat Resistant – Ideal for thermal insulation and reducing building loads.

Environmental Concerns & Challenges

While fly ash has many benefits, improper disposal can cause serious environmental and health issues:

⚠ Air & Water Pollution – If not managed properly, fly ash can contaminate air, water, and soil, affecting ecosystems.

⚠ Toxicity Risks – Fly ash contains trace amounts of heavy metals (arsenic, lead, mercury), which can pose health hazards if inhaled or consumed through water contamination.

⚠ Storage & Disposal Issues – Large quantities of fly ash require proper storage and landfill management.

Sustainable solutions include:

- Recycling fly ash into construction materials.

- Developing advanced technologies for cleaner coal combustion.

- Strict regulations for safe disposal and utilization.

Fly ash, a by-product of coal-fired power plants, has transformed from a waste material into a valuable resource in construction, agriculture, and industry. Its use in cement, concrete, bricks, and road construction makes it a sustainable alternative that reduces environmental impact and promotes resource efficiency.

By maximizing its beneficial applications while ensuring safe handling and disposal, fly ash can contribute to a greener and more sustainable future.

Petroleum

What is Petroleum?

Petroleum, commonly known as crude oil, is a naturally occurring liquid fossil fuel formed over millions of years from the decomposition of ancient marine organisms like plankton and algae. It is found deep beneath the Earth’s surface and is extracted through drilling. Petroleum is one of the most valuable natural resources, serving as a primary source of energy and raw materials for countless industries worldwide.

Formation of Petroleum

Petroleum formation is a slow geological process that takes place over millions of years under high pressure and temperature beneath the Earth’s surface. The process occurs in three main stages:

- Organic Matter Accumulation – Dead marine plants and animals sink to the seafloor and mix with sand and silt, forming organic-rich sediments.

- Burial & Transformation – Over time, these sediments get buried under layers of rock. Heat and pressure transform organic material into hydrocarbons.

- Migration & Trapping – The hydrocarbons move through porous rocks and accumulate in reservoirs, where they remain until extracted by drilling.

Uses of Petroleum

Petroleum is an essential energy source that fuels industries, transportation, and daily life. Its primary uses include:

Transportation Fuels – The most significant use of petroleum is for producing fuels such as:

- Gasoline (Petrol) – Used in cars, motorcycles, and small engines.

- Diesel – Powers trucks, buses, trains, and ships.

- Aviation Fuel – Jet fuel is used for aircraft propulsion.

- Electricity Generation – Petroleum products like fuel oil and natural gas are burned in power plants to produce electricity.

Industrial & Chemical Applications – Petroleum is a key ingredient in manufacturing various products, including:

- Plastics & Synthetic Materials – Used in packaging, electronics, and textiles.

- Lubricants & Waxes – Essential for machinery, car engines, and cosmetics.

- Pharmaceuticals & Fertilizers – Petroleum derivatives are used to produce medicines, pesticides, and fertilizers.

- Household Uses – Many households rely on kerosene and liquefied petroleum gas (LPG) for cooking, heating, and lighting.

- Defense & Space Exploration – Petroleum-based fuels power military equipment, rockets, and satellites.

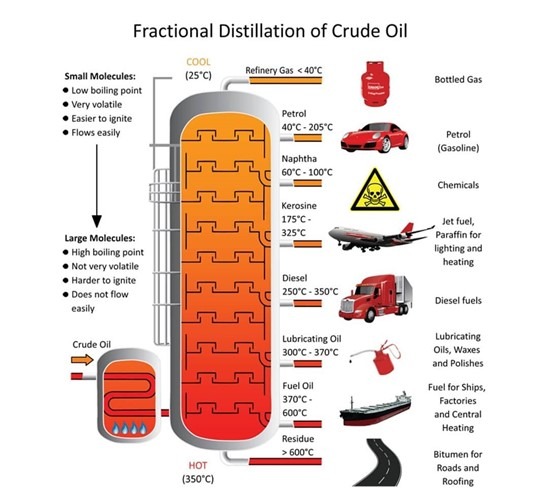

Fractional Distillation: The Refining Process

Since crude oil is a mixture of hydrocarbons, it must undergo refining to separate it into usable petroleum products. The most important refining process is fractional distillation.

What is Fractional Distillation?

Fractional distillation is a physical separation process that breaks crude oil into different fractions based on their boiling points. This process is carried out in a fractionating column in an oil refinery.

How Fractional Distillation Works

- Heating – Crude oil is heated in a furnace until it turns into vapor.

- Separation – The vaporized oil enters a fractionating column, where it rises and cools at different levels.

- Condensation – Each fraction condenses at its specific boiling point and is collected separately.

- Collection – The separated fractions are processed further to produce refined petroleum products.

Main Petroleum Fractions & Their Uses

Fraction | Boiling Point Range | Uses |

Petroleum Gas | Below 40°C | LPG, cooking gas |

Naphtha | 30–90°C | Raw material for petrochemicals |

Gasoline (Petrol) | 40–200°C | Car fuel, solvent |

Kerosene | 150–250°C | Jet fuel, lighting, heating |

Diesel | 200–350°C | Truck & train fuel |

Lubricating Oils | 300–370°C | Engine oil, greases |

Fuel Oil | 350–600°C | Power plants, ship fuel |

Bitumen (Asphalt) | Above 600°C | Road construction, waterproofing |

Advantages of Petroleum

✅ High Energy Content – Produces more energy per unit than most other fuels.

✅ Versatile – Used in multiple industries including transportation, construction, and medicine.

✅ Easily Transportable – Can be transported through pipelines, ships, and tankers.

✅ Reliable & Efficient – Provides consistent energy for vehicles, homes, and industries.

Environmental Concerns & Challenges

- Air Pollution – Burning petroleum releases carbon dioxide (CO₂), sulfur oxides (SOx), and nitrogen oxides (NOx), contributing to climate change and acid rain.

- Oil Spills & Water Pollution – Accidental oil spills harm marine life and coastal ecosystems.

- Non-Renewable Resource – Petroleum reserves are finite, and over-reliance can lead to depletion.

- Health Hazards – Exposure to petroleum fumes can cause respiratory issues and skin problems.

Solutions & Sustainable Alternatives

- Renewable Energy Adoption – Transitioning to solar, wind, and electric vehicles can reduce dependency on petroleum.

- Cleaner Fuel Technologies – Innovations like biofuels and hydrogen fuel cells help minimize environmental impact.

- Efficient Energy Use – Improving fuel efficiency and recycling petroleum-based products can reduce waste.

Petroleum plays an indispensable role in modern life, powering transportation, industries, and households. The refining process, particularly fractional distillation, enables the production of various essential fuels and materials. However, due to its environmental impact and limited supply, the world must balance petroleum use with the development of cleaner, renewable alternatives for a sustainable future.

LPG (Liquefied Petroleum Gas)

What is LPG?

Liquefied Petroleum Gas (LPG) is a highly efficient, portable, and clean-burning fuel consisting primarily of propane (C₃H₈), butane (C₄H₁₀), and isobutane. It is obtained as a byproduct of natural gas processing and crude oil refining. LPG is stored and transported in a liquefied state under pressure, making it easy to handle and use for various applications.

Composition of LPG

LPG is a blend of light hydrocarbons, mainly composed of:

- Propane (C₃H₈) – More volatile and used in colder climates.

- Butane (C₄H₁₀) – Provides higher energy efficiency, commonly used in cooking and lighters.

- Isobutane (C₄H₁₀) – A structural variant of butane with applications in aerosols and refrigeration.

The specific composition of LPG varies based on geographic location and intended use. In warmer regions, butane is preferred, while propane dominates in colder climates due to its lower boiling point.

How is LPG Produced?

LPG is derived from two primary sources:

- Natural Gas Processing – When extracting natural gas, LPG components are separated to prevent condensation in pipelines.

- Crude Oil Refining – During the refining process, LPG is produced as a byproduct when cracking crude oil into gasoline and diesel.

Uses of LPG

LPG is an extremely versatile fuel, serving multiple sectors:

Domestic Uses

- Cooking – The most common use of LPG worldwide, offering instant heat and precise temperature control.

- Heating & Hot Water – Used in room heaters, geysers, and fireplaces.

- Backup Power – LPG generators provide emergency power supply during electricity outages.

Industrial & Commercial Uses

- Metal Cutting & Welding – Used in oxy-LPG torches due to its high-temperature flame.

- Ceramics & Glass Industry – Provides consistent heating for manufacturing processes.

- Food & Beverage Industry – Used for baking, drying, and roasting in commercial kitchens.

Automotive Uses (Autogas)

- Fuel for Vehicles – LPG is used as an alternative to petrol and diesel, reducing emissions and fuel costs.

- Public Transport & Taxis – Many buses, taxis, and fleet vehicles operate on LPG, offering an eco-friendly transportation

Refrigeration & Aerosols

- Aerosol Propellant – LPG is used in deodorants, air fresheners, and spray paints.

- Refrigeration – Serves as an alternative to CFCs, which are harmful to the ozone layer.

Advantages of LPG

✅ Eco-Friendly – Produces fewer carbon emissions compared to coal and diesel.

✅ Energy Efficient – Burns cleanly and completely, with minimal wastage.

✅ Portable & Easy to Store – Can be stored in cylinders or bulk tanks, making it widely accessible.

✅ Safe & Reliable – LPG systems have built-in safety features, and leaks can be easily detected due to added odorants.

✅ Cost-Effective – More affordable than electricity in many regions.

Environmental Concerns & Safety Precautions

- Flammability Risk – LPG is highly flammable, requiring proper storage and handling.

- Leak Hazards – Always check for leaks using soapy water, and never rely solely on smell.

- Storage Guidelines – Keep cylinders in well-ventilated areas, away from direct sunlight and ignition sources.

Emergency Measures for Gas Leaks

- Do not ignite flames or switch on electrical appliances.

- Turn off the gas supply at the cylinder valve.

- Ventilate the area by opening doors and windows.

- Call emergency services if the leak persists.

LPG is a clean, efficient, and widely used fuel that powers homes, industries, and vehicles. Its versatility, portability, and cost-effectiveness make it a preferred choice in many regions. However, proper safety measures should always be followed to prevent accidents. As the world shifts toward cleaner energy sources, LPG remains a transitional fuel, bridging the gap between fossil fuels and renewable energy solutions.

Sweet and Sour Gas

These are types of natural gas. Sweet gas has a low sulphur content, making it less corrosive and more environmentally friendly, while sour gas contains higher amounts of hydrogen sulphide and requires more processing to make it safe to use.

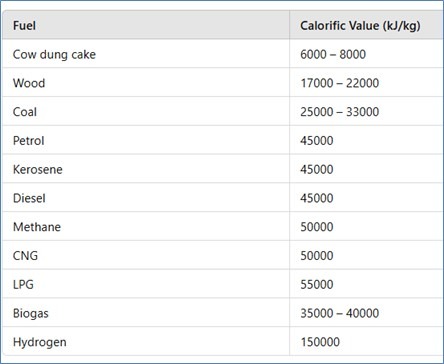

Calorific Value of Fuels

Calorific value is a measure of the amount of heat produced by a unit mass or volume of a substance when it undergoes complete combustion. It’s often expressed in units like kilojoules per kilogram (kJ/kg) or British thermal units per pound (BTU/lb).

RENEWABLE (NON-CONVENTIONAL) ENERGY RESOURCES

Renewable energy sources are varied and sustainable, unlike finite resources such as coal and petroleum. These sources encompass solar, wind, geothermal, hydropower, and ocean energy, which includes Ocean Thermal Energy Conversion (OTEC) and tidal energy. Additionally, biomass energy, such as biofuels, and wave energy are also part of this category. Each of these energy sources possesses unique characteristics and classifications.

1. SOLAR ENERGY

2. WIND ENERGY

3. GEO THERMAL ENERGY

4. METHODS

5. HYDRO POWER

6. GAS HYDRATES

7. BIOMASS ENERGY

Solar Energy

Solar energy is one of the purest, most abundant, and sustainable sources of renewable energy available today. It has the highest potential among all renewable energy sources due to the limitless supply of sunlight. With advancements in technology, solar power has become a reliable and cost-effective alternative to fossil fuels, contributing to energy security and environmental sustainability.

Solar power works by harnessing the energy of the sun and converting it into electricity using photovoltaic (PV) technology or generating heat using solar thermal technology. Solar panels, made up of semiconductive materials like silicon, are designed to capture and convert sunlight into electricity, making them an efficient and eco-friendly solution for residential, commercial, and industrial applications.

Types of Solar Power Systems

1. Photovoltaic (PV) Systems: Converting Sunlight into Electricity

Photovoltaic (PV) systems directly convert sunlight into electricity using solar cells. These systems are widely used in homes, commercial buildings, and large-scale solar farms to generate clean and renewable energy.

How Do PV Systems Work?

The photovoltaic effect is the principle behind PV systems:

- Solar cells, primarily made of silicon, absorb sunlight.

- Sunlight excites electrons, generating an electric current.

- The current is collected and converted into usable electricity for residential, commercial, or industrial purposes.

- PV systems are modular and can range from small rooftop panels to large solar farms that supply electricity to the grid.

2. Concentrated Solar Power (CSP): Using Heat for Power Generation

Unlike PV systems, Concentrated Solar Power (CSP) uses mirrors or lenses to focus sunlight onto a receiver. This concentrated sunlight produces high temperatures, generating steam that drives a turbine connected to an electrical generator.

Types of CSP Systems

✅ Parabolic Troughs – Curved mirrors focus sunlight onto a tube carrying heat-absorbing fluid.

✅ Solar Power Towers – Large arrays of mirrors focus sunlight onto a central tower with a heat-absorbing medium.

✅ Dish-Engine Systems – A parabolic dish focuses sunlight onto a receiver, generating mechanical power.

CSP is primarily used for large-scale power generation and is an efficient solution for grid-based electricity supply.

Difference Between Solar PV Panels and Solar Thermal Panels

Feature | Solar Photovoltaic (PV) Panels | Solar Thermal Panels |

Purpose | Convert sunlight into electricity | Convert sunlight into heat |

Technology | Uses semiconductor-based solar cells | Uses heat-absorbing fluid |

Application | Powering homes, businesses, and grids | Heating water and space |

Energy Output | Electricity | Thermal Energy |

Efficiency | Dependent on sunlight exposure and panel efficiency | Highly efficient in solar water heating and industrial heating |

PV panels are designed primarily for electricity generation, while solar thermal panels are used for heating water, air, and industrial processes.

Solar Power Applications

1. Solar Water Pumps: Harnessing the Sun for Water Supply

A solar water pump is an electrically powered pump system that utilizes solar energy instead of conventional electricity. These pumps reduce dependency on diesel or grid electricity and are commonly used in agriculture, drinking water supply, and irrigation systems.

Types of Solar Water Pumps:

- Submersible Pumps – Operate deep underwater, ideal for borewells.

- Surface Pumps – Used for shallow water sources such as rivers and ponds.

- Direct Current (DC) Pumps – Work directly on solar power, highly efficient.

- Alternative Current (AC) Pumps – Require an inverter to convert solar power to AC electricity.

These pumps help farmers irrigate fields efficiently, reducing operational costs and environmental impact.

2. Solar Rooftop Systems: Powering Homes & Businesses

Solar rooftop systems are installed on residential, commercial, and industrial buildings to generate electricity. These systems:

- Reduce electricity bills by producing power onsite.

- Can be grid-connected (feed excess electricity back to the grid).

- Require low maintenance and have a lifespan of 25+ years.

Government subsidies and incentives make solar rooftop installations affordable and accessible to homeowners and businesses.

3. Solar Parks: Large-Scale Solar Energy Generation

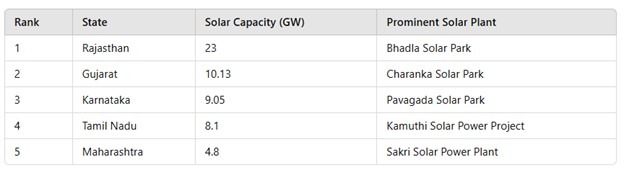

Solar parks are vast solar farms consisting of hundreds of thousands of solar panels deployed on open land to generate large amounts of electricity. These installations are typically developed by governments, private firms, or through public-private partnerships (PPPs). Solar parks contribute significantly to national energy grids and help reduce dependence on fossil fuels.

Current Solar Energy Capacity and Future Growth in India

India is emerging as a global leader in solar power adoption, aiming to achieve 500 GW of renewable energy capacity by 2030.

Key Statistics (as of October 2024):

- India’s installed solar capacity stands at approximately 94.17 GW (MNRE).

- The country has witnessed a 30-fold increase in solar installations over the past nine years.

- Several mega solar parks have been established in states like Rajasthan, Gujarat, and Karnataka.

- Government initiatives such as PM-KUSUM and solar subsidies are promoting solar adoption in rural and urban areas.

Advantages of Solar Energy

1. Environmental Benefits

- Zero Carbon Emissions – No greenhouse gas emissions during operation.

- Reduces Air & Water Pollution – Unlike coal or fossil fuels, solar energy does not produce harmful pollutants.

- Conserves Water – Requires minimal water for maintenance compared to thermal power plants.

2. Economic Benefits

- Reduces Electricity Bills – Consumers can save significantly on electricity costs.

- Energy Independence – Reduces dependency on imported fossil fuels.

- Job Creation – The solar industry provides employment opportunities in manufacturing, installation, and maintenance.

3. Reliability & Accessibility

- Works in Remote Areas – Ideal for off-grid applications where traditional electricity is unavailable.

- Low Maintenance – Solar panels have a long lifespan with minimal upkeep.

- Scalability – Solar systems can be expanded easily based on energy needs.

Challenges & Solutions

1. High Initial Investment

❌ Solar installation costs can be expensive.

✅ Solution: Government incentives, tax benefits, and financing options help offset costs.

2. Energy Storage Limitations

❌ Solar power generation depends on sunlight availability.

✅ Solution: Battery storage systems (like lithium-ion batteries) store excess energy for nighttime or cloudy days.

3. Land Requirements for Large-Scale Projects

❌ Solar farms require vast land areas.

✅ Solution: Floating solar farms on water bodies optimize space usage.

Solar energy is a game-changer in the transition toward a clean and sustainable energy future. With advancements in solar technology, government support, and cost reductions, solar power is rapidly becoming one of the most viable energy sources globally.

Whether through solar rooftops, water pumps, or large-scale solar parks, adopting solar energy can significantly reduce carbon footprints, lower energy costs, and contribute to a greener planet.

Areas of Presence: Solar energy projects are spread across various states in India.

Wind Energy

Wind energy is one of the fastest-growing renewable energy sources in the world. It involves converting the kinetic energy of moving air into electricity using wind turbines. As the wind blows, it turns the blades of a turbine, which, in turn, spins a generator to produce electricity.

Wind energy is a clean, sustainable, and cost-effective alternative to fossil fuels, playing a crucial role in reducing greenhouse gas emissions and combating climate change. The use of wind power has seen significant growth globally, with countries investing heavily in wind farms to meet their energy needs.

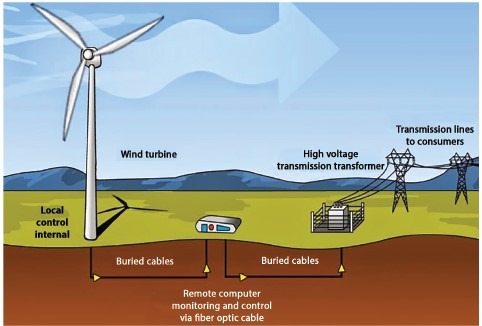

How Does Wind Energy Work?

The process of generating electricity from wind involves the following steps:

- Wind Turbines Capture Wind Energy – The movement of air rotates the turbine blades.

- Conversion of Kinetic Energy to Mechanical Energy – The blades are connected to a shaft, which transfers the rotational force to a generator.

- Electricity Generation – The generator converts this mechanical energy into usable electricity, which is then fed into the grid or used locally.

Wind power can be harnessed on land (onshore wind farms) or over water (offshore wind farms), depending on the location and wind conditions.

Types of Wind Farms / Parks

1. Offshore Wind Farms: Powering the Future from the Seas

Offshore wind power refers to wind farms that are constructed over bodies of water, usually in oceans, seas, lakes, or fjords. These locations have higher wind speeds compared to land, making them highly efficient for electricity generation.

Advantages of Offshore Wind Energy

✅ Higher Energy Yield – Offshore wind farms can accommodate larger and taller turbines, allowing for greater electricity production.

✅ Stronger & Consistent Wind Speeds – The open sea experiences fewer obstructions (such as buildings or mountains), resulting in higher wind speeds and energy generation.

✅ Reduced Land Usage Conflicts – Offshore wind farms do not occupy valuable land resources, making them ideal for densely populated regions.

✅ Minimal Visual & Noise Impact – Being far from urban areas, offshore wind farms cause less disturbance to people.

✅ Potential for Large-Scale Energy Production – With technological advancements, wind farms can now be built further into deeper waters, increasing their potential to generate electricity.

Many countries, including India, the USA, the UK, and China, are investing in offshore wind energy to enhance their renewable energy capacity.

2. Onshore Wind Farms: Land-Based Wind Energy Solutions

Onshore wind power refers to wind turbines installed on land. These turbines are typically set up in open plains, hills, and remote areas where wind speeds are sufficient to generate electricity.

Advantages of Onshore Wind Energy

✅ Lower Installation and Maintenance Costs – Onshore wind farms are cheaper to install than offshore wind farms, making them a cost-effective renewable energy option.

✅ Easier Access for Repairs & Maintenance – Unlike offshore farms, onshore turbines are easier to maintain, reducing operational costs.

✅ Proximity to Energy Consumers – Since they are located closer to cities and industries, less energy is lost during transmission.

✅ Quick Installation – A wind turbine can be set up within months, whereas nuclear power plants or coal plants take years to construct.

India has vast potential for onshore wind energy, with states like Tamil Nadu, Gujarat, Maharashtra, and Karnataka leading in installations.

Comparing Offshore and Onshore Wind Energy

Feature | Offshore Wind Farms | Onshore Wind Farms |

Location | Built over oceans, seas, or large water bodies | Installed on land in open, windy areas |

Wind Speed | Higher wind speeds, more consistent | Wind speed varies due to terrain |

Energy Output | Greater energy generation potential | Lower energy yield per turbine |

Installation Cost | Expensive to install & maintain | More affordable to set up |

Maintenance | Difficult & costly due to ocean conditions | Easier & cost-effective |

Visual & Noise Impact | Minimal impact, as they are far from people | Can cause some visual and noise disturbance |

Land Usage | No land required | Requires land space for installation |

Both offshore and onshore wind farms have their unique benefits and challenges. The choice between them depends on geographical, economic, and environmental factors.

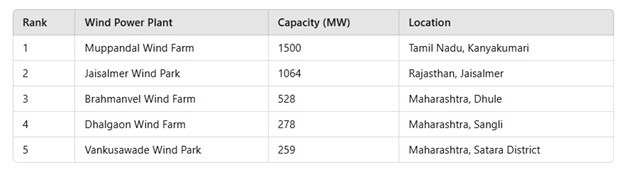

Current Wind Energy Capacity & Growth in India

Installed Capacity (as of October 2024):

India’s total installed wind energy capacity stands at 47.72 GW (gigawatts), making it one of the largest wind energy producers globally.

Key Wind Energy States in India:

- Tamil Nadu – The largest wind energy producer in India, with strong coastal winds.

- Gujarat – Ideal wind conditions for both onshore and offshore wind farms.

- Maharashtra – A major contributor to India’s wind energy sector.

- Karnataka – Home to several large wind farms, taking advantage of favorable wind patterns.

The Indian government aims to rapidly expand wind power capacity, with ambitious targets set under the National Offshore Wind Energy Policy and Green Energy Corridors.

Benefits of Wind Energy

1. Environmental Benefits

- Zero Carbon Emissions – Wind energy is 100% clean and renewable.

- Prevents Air & Water Pollution – Unlike fossil fuels, wind turbines do not release harmful pollutants.

- Saves Water – Wind energy requires no water for operation, unlike coal or nuclear power plants.

2. Economic & Social Benefits

- Creates Jobs – The wind energy sector generates employment opportunities in manufacturing, installation, and maintenance.

- Reduces Electricity Costs – Wind power is becoming cheaper due to technological advancements.

- Boosts Energy Security – By reducing dependence on imported fossil fuels, wind power enhances national energy security.

3. Reliability & Sustainability

- Abundant & Renewable – Wind is an inexhaustible natural resource.

- Energy for Rural Areas – Wind power helps electrify remote areas with little access to conventional electricity.

Challenges & Solutions in Wind Energy

1. Intermittent Nature of Wind Energy

❌ Wind is not always consistent, leading to fluctuations in power generation.

✅ Solution: Battery storage systems and hybrid energy solutions (like solar-wind integration) can provide a stable power supply.

2. Land & Environmental Concerns

❌ Large-scale wind farms require significant land areas.

✅ Solution: Proper site selection and offshore wind expansion can help reduce land conflicts.

3. Initial High Investment Costs

❌ Wind energy infrastructure can be expensive upfront.

✅ Solution: Government incentives, tax benefits, and international funding can help make wind energy more accessible.

Wind energy is one of the most promising solutions to achieve a clean, green, and sustainable energy future. With rapid advancements in wind turbine technology, offshore wind development, and grid integration, wind power is set to play a major role in the global energy transition.

India, with its vast wind potential, is well-positioned to become a global leader in wind energy. By continuing to invest in wind power infrastructure, adopting innovative technologies, and expanding offshore wind farms, the country can reduce its carbon footprint and achieve energy independence.

Wind Parks: India has developed several large wind parks. Examples include

Geothermal Energy

Geothermal energy is a renewable energy source derived from the natural heat of the Earth’s interior. This heat originates from the radioactive decay of minerals and the residual heat from the planet’s formation. It is stored in the Earth’s crust and can be harnessed for electricity generation, direct heating, and other applications.

This form of energy is particularly abundant in regions with volcanic activity, hot springs, geysers, and tectonic plate boundaries. Countries such as Iceland, the USA, Indonesia, and the Philippines have successfully utilized geothermal energy for decades, making it a key player in the global transition to clean energy.

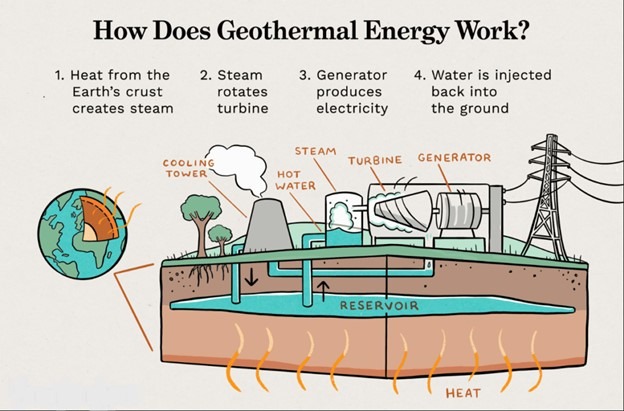

How Geothermal Energy Works

The Earth’s interior consists of magma, molten rock, and high-temperature reservoirs that emit heat. This heat naturally escapes through the Earth’s surface in the form of hot springs, steam vents, and volcanic eruptions. To harness this energy, engineers drill deep wells into geothermal reservoirs to tap into the high-temperature water or steam below the Earth’s surface. This heat can then be converted into electricity or used directly for heating.

Key Steps in Geothermal Power Generation

- Heat Extraction – Wells are drilled deep underground to access hot water or steam.

- Power Generation – The steam rotates a turbine connected to a generator, producing electricity.

- Reinjection Process – The cooled water is injected back into the Earth’s crust to maintain sustainability.

Types of Geothermal Energy Systems

1. Geothermal Power Plants (Electricity Generation)

Geothermal power plants convert heat energy into electricity through three main systems:

A. Dry Steam Power Plants

✅ The oldest and most efficient geothermal power plants.

✅ Extracts steam directly from underground geothermal reservoirs to spin a turbine and generate electricity.

✅ Example: The Geysers in California, USA, the world’s largest geothermal steam field.

B. Flash Steam Power Plants

✅ Uses high-pressure hot water from underground reservoirs.

✅ When brought to the surface, the pressure drops, turning the water into steam, which drives the turbine.

✅ Flash steam plants are the most common type of geothermal power plants.

C. Binary Cycle Power Plants

✅ Uses a secondary liquid (binary fluid) with a lower boiling point than water.

✅ Heat from the geothermal water causes the binary fluid to evaporate, spinning a turbine to generate electricity.

✅ Best suited for areas with moderate geothermal temperatures (100-200°C).

✅ More environmentally friendly as they emit almost zero greenhouse gases.

2. Direct Use of Geothermal Energy

Geothermal energy is not just for electricity—it can be directly used for heating applications, including:

- District Heating Systems – Provides centralized heating for buildings, homes, and industries.

Hot Springs & Spa Resorts – Naturally occurring hot springs are used for therapeutic bathing. - Agriculture & Greenhouses – Farmers use geothermal heat for crop production in colder regions.

- Industrial Uses – Industries use geothermal energy for drying timber, milk pasteurization, and textile production.

- District Heating Systems – Provides centralized heating for buildings, homes, and industries.

3. Geothermal Heat Pumps (GHPs)

Unlike power plants, geothermal heat pumps (also called ground-source heat pumps) use the Earth’s stable underground temperature to provide heating and cooling for residential and commercial buildings.

- Winter: Absorbs heat from the ground and transfers it indoors.

- Summer: Removes indoor heat and transfers it underground for cooling.

- Highly energy-efficient and cost-effective, reducing heating and cooling bills by up to 50% compared to conventional systems.

Properties & Advantages of Geothermal Energy

- Renewable & Sustainable – Unlike fossil fuels, geothermal energy is naturally replenished by the Earth.

- Reliable & Consistent – Unlike solar and wind energy, geothermal energy is available 24/7, unaffected by weather conditions.

- Low Carbon Footprint – Produces minimal greenhouse gas emissions, helping combat climate change.

- Cost-Effective – Once installed, geothermal power plants have low operating costs compared to coal or gas plants.

- Versatile Applications – Used for electricity, heating, and industrial processes.

Current Capacity & Growth of Geothermal Energy

Global Installed Capacity (2024): Over 16 GW of geothermal power is currently in operation worldwide.

Top Geothermal Energy Producing Countries:

- United States – The largest producer, generating over 3.7 GW.

- Indonesia – Rapidly expanding, currently at 8 GW.

- Philippines – A key player in Southeast Asia, producing 9 GW.

- Iceland – A leader in geothermal utilization, with 90% of homes heated using geothermal energy.

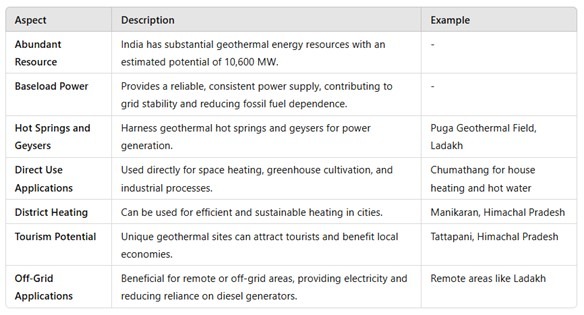

India’s Geothermal Energy Potential:

India is exploring geothermal energy in regions like Ladakh, Himachal Pradesh, and Chhattisgarh, with the Puga Valley in Ladakh identified as a prime location for future geothermal power plants.

Challenges & Solutions in Geothermal Energy

1. High Initial Investment Costs

- Drilling wells and setting up geothermal plants require significant capital.

- Solution: Government subsidies, tax incentives, and international funding can help make projects financially viable.

2. Limited Geographic Availability

- Only certain regions have sufficient geothermal activity for power generation.

- Solution: Developing binary cycle plants can make use of moderate-temperature resources.

3. Potential Environmental Concerns

- In some cases, drilling can trigger minor seismic activity.

- Solution: Advanced monitoring and better site selection can minimize risks.

Future of Geothermal Energy

With advancements in drilling technology, enhanced geothermal systems (EGS), and growing investments, geothermal energy is set to become a major contributor to global renewable energy goals.

- Governments and organizations worldwide are increasing investments to expand geothermal energy capacity.

- Innovations in deep drilling technology are unlocking new geothermal reservoirs for energy production.

- Hybrid energy solutions (such as geothermal-solar or geothermal-wind integration) are improving efficiency and reliability.

As the world shifts towards clean energy, geothermal power stands as one of the most promising and sustainable sources of energy for the future!. Geothermal energy is a powerful, renewable, and highly reliable energy source with enormous potential. Its ability to provide continuous, low-carbon electricity and heating makes it an essential part of the global transition to sustainable energy.

India and other countries can unlock the power of geothermal resources by investing in research, adopting new technologies, and expanding geothermal infrastructure. With proper development, geothermal energy can play a crucial role in meeting future energy demands while protecting the environment.

Methods

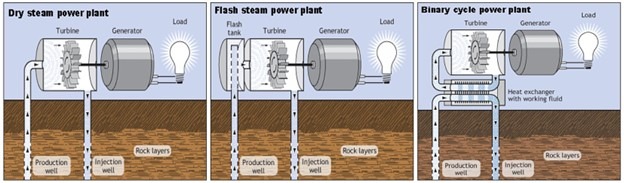

Geothermal energy production varies based on geological conditions, resource availability, and temperature levels. There are three primary methods used to harness geothermal energy, each suited for different types of geothermal reservoirs. These methods are:

1. Dry Steam Power Plants

Dry steam power plants are the oldest and most efficient type of geothermal power generation. This method utilizes natural underground steam directly from geothermal reservoirs to rotate turbines and generate electricity.

How It Works:

✔ High-pressure steam from underground is piped directly to a turbine.

✔The steam expands, turning the turbine blades to generate electricity.

✔After use, the steam is cooled and condensed into water, which is then reinjected back into the reservoir to maintain sustainability.

Key Characteristics:

- Highly efficient – No need for additional heat exchangers or complex processing.

- Requires naturally occurring steam reservoirs, which are less common.

- Minimal greenhouse gas emissions since steam is directly used.

Ideal Locations:

- The Geysers, California (USA) – The largest dry steam geothermal field in the world.

- Larderello, Italy – One of the first regions to use dry steam technology for power production.

2. Flash Steam Power Plants

Flash steam power plants are the most widely used geothermal energy production method and are suitable for high-temperature geothermal reservoirs where water is stored at over 182°C (360°F). These reservoirs contain pressurized hot water deep underground, which turns into steam when brought to the surface.

How It Works:

✔ Superheated water (above 182°C) is brought to the surface through deep wells.

✔As the water rises, the drop in pressure causes some of it to “flash” into steam.

✔This steam drives a turbine, generating electricity.

✔Any remaining liquid water is returned to the reservoir to sustain production.

Key Characteristics:

- More widely applicable than dry steam plants because high-temperature water is more common than pure steam.

- Highly efficient, as it utilizes both steam and water.

- Requires deep geothermal wells to access high-temperature water sources.

Ideal Locations:

- Taupo Volcanic Zone, New Zealand – Home to several flash steam geothermal plants.

- Cerro Prieto, Mexico – One of the largest flash steam geothermal plants in the world.

3. Binary Cycle Power Plants

Binary cycle power plants are designed for lower-temperature geothermal reservoirs (typically 107-182°C (225-360°F)). Unlike dry steam and flash steam plants, these systems do not use steam directly from underground sources. Instead, they transfer heat from geothermal water to a secondary working fluid with a low boiling point, such as an organic compound (e.g., isobutane or pentane).

How It Works:

✔ Hot geothermal water is pumped to the surface and passed through a heat exchanger.

✔ This heat is transferred to a secondary liquid with a lower boiling point than water.

✔ The secondary liquid evaporates into a vapor, which then drives a turbine to generate electricity.

✔ The geothermal water is reinjected into the ground, ensuring sustainability.

Key Characteristics:

- Suitable for moderate-temperature geothermal resources, making it widely applicable.

- Produces zero emissions because geothermal water never comes into direct contact with the atmosphere.

- More environmentally friendly and can be deployed in more locations than dry or flash steam plants.

- More expensive initial setup, but lower environmental impact and higher adaptability.

Ideal Locations:

- Chena Hot Springs, Alaska (USA) – One of the first binary cycle geothermal plants in a cold climate.

- Germany and Japan – Widely used for low-to-moderate-temperature geothermal resources.

Comparison of Geothermal Power Plant Technologies

Feature | Dry Steam | Flash Steam | Binary Cycle |

Temperature Required | Very high (>235°C) | High (>182°C) | Moderate (107-182°C) |

Steam Used Directly? | Yes | Partially | No (uses a heat exchanger) |

Efficiency | High | High | Moderate |

Greenhouse Gas Emissions | Very Low | Low | Zero |

Technology Complexity | Simple | Moderate | More complex |

Geographical Suitability | Limited (steam reservoirs only) | More common | Most widespread |

Future of Geothermal Energy Production

As geothermal energy continues to grow as a sustainable and renewable power source, advancements in drilling techniques and Enhanced Geothermal Systems (EGS) will allow geothermal power to be harnessed in more locations. The development of binary cycle plants is also expected to expand geothermal energy use, as they can operate with lower temperatures and virtually no emissions.

With further research and investment, geothermal energy could play a major role in global electricity generation, contributing to a cleaner and greener future.

Current Capacity and Potential:

Installed Capacity: As of 2024, India has not yet started commercial power production from geothermal energy. However, the potential is significant. Site exploration is currently going on in Puga Valley of Ladakh. India is also exploring sites in the state of Arunachal Pradesh.

Potential Capacity: Estimates suggest that India has the capacity to generate around 10 GW of geothermal energy.

Hydropower

Hydropower, also known as hydroelectric power, is one of the most significant renewable energy sources, utilizing the natural movement of water to generate electricity. By harnessing the kinetic energy of flowing or falling water, hydropower plants drive turbines connected to electric generators, providing a clean, efficient, and reliable energy source.

Key Characteristics of Hydropower

- Renewable & Sustainable – Hydropower depends on the natural water cycle, making it an inexhaustible energy source.

- Low Carbon Emissions – Unlike fossil fuels, hydropower does not release carbon dioxide or other greenhouse gases, reducing its environmental footprint.

- High Efficiency – Modern hydroelectric plants can convert 90% of available energy into electricity, significantly higher than other renewable sources.

- Flexible & Scalable – Hydropower plants can quickly adjust to fluctuations in electricity demand, making them ideal for maintaining grid stability.

- Long Lifespan – Hydroelectric facilities can operate for over 50-100 years with proper maintenance, making them a long-term energy investment.

Types of Hydropower Plants

1. Large Hydropower Plants (Dam-Based Hydropower)

Large hydropower plants typically involve building dams across rivers to store water in reservoirs. The stored water is then released through turbines to generate electricity.

Advantages:

✔Provides a continuous and stable power supply.

✔Can store water for flood control and irrigation.

✔Helps in water supply management for agriculture and drinking water.

Environmental & Social Impacts:

Can cause displacement of local communities.

Alters aquatic ecosystems, affecting fish migration and river biodiversity.

Large reservoirs may contribute to methane emissions due to organic material decomposition.

2. Small Hydropower Plants (Run-of-River Systems)

Small hydro projects generate electricity without the need for large reservoirs. Instead, they divert part of a river’s flow to turbines and return the water to the stream.

Advantages:

✔Minimal environmental impact compared to large dams.

✔Suitable for remote and rural areas.

✔Can operate without disrupting the natural flow of rivers.

Challenges:

Output depends on seasonal river flow variations.

May generate less electricity compared to large hydro projects.

3. Pumped-Storage Hydropower (PSH) – Energy Storage Solution

Pumped-storage hydropower is a crucial technology for energy storage, enabling electricity grids to store surplus energy during low demand and release it when needed.

How It Works:

During periods of low electricity demand, excess energy is used to pump water from a lower reservoir to an upper reservoir.When energy demand increases, the stored water is released back down to the lower reservoir, passing through turbines to generate electricity.This system acts as a giant natural battery, ensuring grid stability and energy reliability.

Advantages of Pumped-Storage Hydropower:

- Provides large-scale energy storage, balancing energy supply and demand.

- Supports grid stability by responding to fluctuations in renewable energy generation (e.g., solar and wind).

- Stores excess energy from renewable sources, reducing reliance on fossil fuels.

- Unlike batteries, PSH has virtually unlimited storage capacity over long periods.

Challenges:

- Requires suitable geography with access to two reservoirs at different elevations.

- Initial construction costs can be high, though long-term benefits outweigh costs.

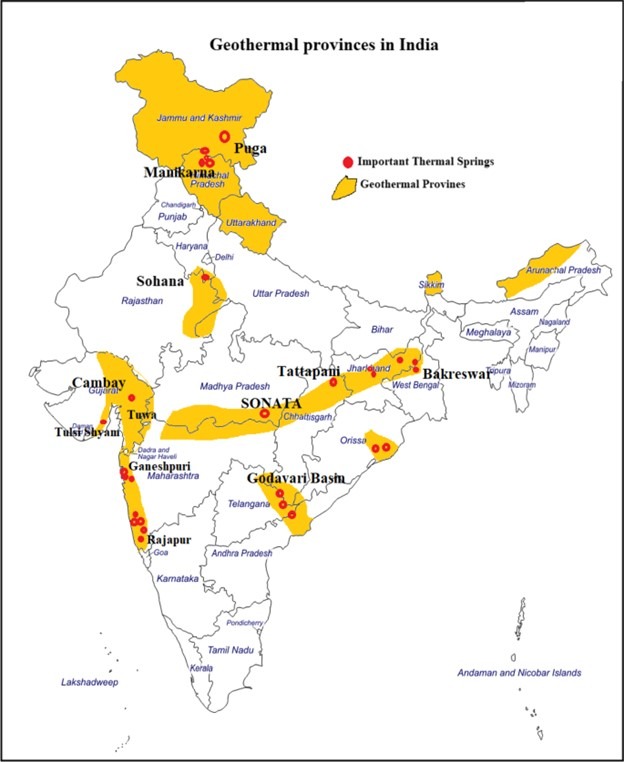

Current Capacity and Growth of Hydropower in India

As of October 10, 2024, India’s total installed hydroelectric capacity stands at 51.99 GW, making it one of the largest contributors to the country’s renewable energy mix.

Large Hydropower Capacity: 46.92 GW

Small Hydropower Capacity: 5.07 GW

Geographical Spread of Hydropower Projects in India

Hydropower projects are primarily located in hilly and river-rich regions with high water flow potential. Some of the key states with major hydropower installations include:

- Himachal Pradesh – Home to Bhakra Nangal Dam and several small hydro projects.

- Uttarakhand – Major projects include Tehri Dam (one of India’s largest).

- Sikkim & Arunachal Pradesh – Emerging hydropower hubs in Northeast India.

- Jammu & Kashmir – Houses several run-of-river projects utilizing the Himalayas’ water sources.

- Kerala & Karnataka – Significant small and medium hydropower projects.

Hydropower’s Role in India’s Energy Transition

India is actively expanding its renewable energy capacity, with hydropower playing a vital role in achieving net-zero emissions by 2070. The government is also investing in pumped-storage hydropower (PSH) projects to improve energy storage and grid stability.

National Hydroelectric Power Corporation (NHPC) is leading large-scale hydro developments.

India is exploring hybrid energy solutions that combine hydropower with solar and wind for better energy security.

Future Goals for Hydropower in India

- Expansion of pumped-storage hydropower projects to manage renewable energy fluctuations.

- Development of more small hydropower projects to electrify rural and remote areas.

- Modernization and efficiency improvements in existing hydropower stations.

- Enhanced environmental regulations to minimize ecological impact.

Hydropower as a Key Energy Solution

Hydropower remains a cornerstone of India’s renewable energy sector, offering clean, reliable, and sustainable power. While large dams may have environmental challenges, advancements in run-of-river systems and pumped-storage technology are making hydropower more adaptable and eco-friendly.

With India’s growing energy needs, hydropower will continue to play a crucial role in the transition towards a green and resilient energy future

Ocean Energy

Ocean energy is an emerging renewable energy source that taps into the vast energy potential of the world’s oceans. The energy stored in ocean waves, tides, currents, and thermal gradients can be converted into electricity, making it a sustainable and inexhaustible power source. India, with its 7,500 km long coastline, has immense potential for developing ocean-based energy solutions to diversify its renewable energy portfolio.

Types of Ocean Energy Technologies

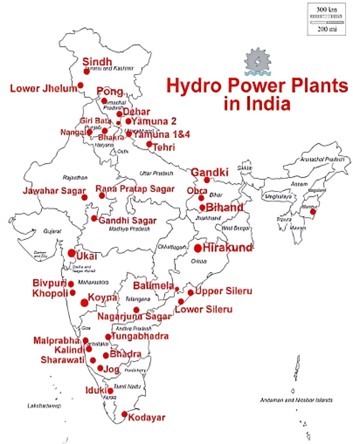

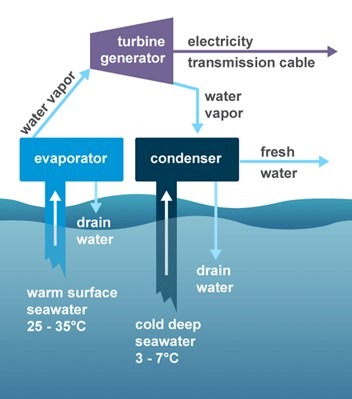

1. Ocean Thermal Energy Conversion (OTEC)

Ocean Thermal Energy Conversion (OTEC) is a technology that utilizes the temperature difference between warm surface waters and cold deep-sea waters to generate electricity. This temperature gradient can drive a heat engine, producing clean and continuous energy.

Working Principle of OTEC:

Warm surface seawater is used to heat a low-boiling-point liquid (e.g., ammonia), converting it into steam.

The steam drives a turbine, generating electricity.

Cold deep-sea water is then used to condense the steam back into liquid, allowing for a continuous cycle.

Advantages of OTEC:

Unlimited energy potential in tropical coastal regions.

Can provide base-load electricity (operates 24/7).

Byproducts include desalinated water, supporting fresh water supply.

Helps in carbon capture, as deep-sea water is rich in CO₂-absorbing nutrients.

Challenges:

High initial costs and technological barriers.

Requires a significant temperature gradient (more than 20°C) between surface and deep water.

Environmental concerns related to the movement of deep-sea water affecting marine ecosystems.

2. Tidal Energy

Tidal energy is generated by harnessing the rise and fall of ocean tides caused by the gravitational interactions between the Earth, Moon, and Sun.

Types of Tidal Energy Systems:

- Ideal Barrage Systems: Large dams or barrages are built at tidal estuaries to trap water at high tide and release it through turbines during low tide.

- Ideal Stream Generators: Underwater turbines function like wind turbines but are powered by moving water instead of air.

- Dynamic Tidal Power (DTP): A theoretical approach that uses long dams extending into the ocean to capture tidal flows.

Advantages of Tidal Energy:

- Highly predictable and reliable – Unlike wind and solar, tides follow fixed lunar cycles.

- High energy density – Water is 800 times denser than air, making tidal turbines more effective than wind turbines.

- Minimal land use – Tidal farms are offshore, avoiding land acquisition challenges.

Challenges:

- Expensive construction and maintenance.

- Can impact marine life and ecosystems in estuaries.

- Limited suitable locations for large-scale tidal energy projects.

3. Wave Energy

Wave energy is generated by capturing the kinetic and potential energy of ocean waves and converting it into electricity. Unlike tidal energy, which depends on the Moon’s gravitational pull, wave energy is influenced by wind patterns over the ocean.

How Wave Energy Works:

Floating or submerged devices move up and down with waves, driving turbines to generate electricity.

Some technologies use hydraulic pumps or air chambers to capture wave energy and convert it into usable power.

Advantages of Wave Energy:

- Abundant energy source, as oceans cover 70% of Earth’s surface.

- High energy output compared to other renewables.

- Suitable for off-grid power generation in coastal communities.

Challenges:

- Wave intensity varies with seasonal and weather changes.

- High technology costs and maintenance issues due to corrosion and storms.

- Potential impact on marine navigation and ecosystems.

4. Ocean Currents Energy

Ocean currents, such as the Gulf Stream, contain massive amounts of kinetic energy that can be converted into electricity using underwater turbines.

Advantages:

- Constant and predictable source of energy.

- High energy density due to the movement of water.

- Minimal visual impact, as installations are submerged underwater.

Challenges:

- Limited to regions with strong ocean currents.

- Requires large-scale infrastructure and high capital investment.

- Environmental concerns related to marine habitat disturbances.

Current Capacity and Potential of Ocean Energy in India

Installed Capacity:

As of 2024, India has not yet achieved significant commercial capacity in ocean energy. However, research and pilot projects are being undertaken to explore its feasibility.

Potential Capacity:

India is estimated to have a theoretical potential of about 54 GW of ocean energy, including tidal, wave, and OTEC energy sources.

Identified Potential Sites:

Tidal Energy Hotspots:

- Gulf of Kutch (Gujarat) – Strong tidal currents make it an ideal location.

- Gulf of Cambay (Gujarat) – One of India’s most promising tidal energy sites.

Wave Energy Potential:

- Western coastline – Arabian Sea has strong waves, ideal for energy generation.

- Eastern coastline – Bay of Bengal has moderate wave energy potential.

OTEC Potential Sites:

Lakshadweep and Andaman & Nicobar Islands – High temperature differentials make them suitable for OTEC projects.

Future Prospects and Government Initiatives

- The Indian government, through the Ministry of New and Renewable Energy (MNRE), is promoting ocean energy research and development. Some key initiatives include:

- National Institute of Ocean Technology (NIOT) conducting OTEC feasibility studies.

- Pilot tidal energy projects in Gujarat.

- Wave energy prototypes under development for coastal electrification.

Collaboration with international partners to advance ocean energy technology.

The Future of Ocean Energy in India

Ocean energy has immense untapped potential to complement India’s renewable energy transition. While high costs and technological challenges remain, continued research, government support, and international collaboration can unlock the vast power of the seas.

As India moves towards its goal of 500 GW of renewable energy by 2030, ocean energy could emerge as a critical component in ensuring sustainable, reliable, and clean electricity for the future.

Gas Hydrates

Gas hydrates are solid, crystalline, ice-like compounds in which gas molecules are trapped within a lattice of water molecules. These unique compounds form naturally under conditions of low temperature and high pressure, typically in deep-sea sediments and permafrost regions. The most common type of gas hydrate contains methane (CH₄), earning it the name methane hydrate or flammable ice. Other gases, such as ethane, propane, and carbon dioxide, can also be present in gas hydrate formations.

With massive reserves found worldwide, gas hydrates are increasingly recognized as a potential future energy resource that could revolutionize the global energy sector. However, challenges related to their extraction, stability, and environmental impact need to be addressed before they can be commercially viable.

Formation of Gas Hydrates

Gas hydrates form naturally when water molecules arrange themselves into cage-like crystalline structures around gas molecules under specific low-temperature and high-pressure conditions. These conditions are typically found in:

- Deep-sea sediments along continental margins, where cold temperatures and high pressures exist.

- Permafrost regions in Arctic and sub-Arctic environments, where underground ice layers trap gas hydrates.

In these locations, methane and other gases—produced from the breakdown of organic material by microbes—become trapped within ice-like structures, preventing their escape into the atmosphere.

Locations of Gas Hydrates

Gas hydrate deposits have been discovered worldwide, with major reserves found in both marine and permafrost environments. Some of the most prominent locations include:

1. Marine Sediments (Deep-Sea Deposits)

Gas hydrates are primarily found in continental margins—underwater regions where continents meet the deep ocean. These areas provide ideal pressure and temperature conditions for hydrate formation.

- Indian Ocean (Krishna-Godavari Basin, Andaman Sea, Mahanadi Basin, Western Offshore regions)

- Gulf of Mexico

- Cascadia Margin (off the coast of the US and Canada)

- Japan Trench and Nankai Trough (Pacific Ocean)

- South China Sea

2. Permafrost Regions (Arctic and Sub-Arctic)

Gas hydrates are also present in frozen permafrost soils, where underground layers of ice and organic material lock in methane. Key locations include:

- Siberia (Russia)

- Alaska (USA)

- Canada (Mackenzie Delta and Arctic islands)

- Greenland

- Norway’s Barents Sea region

According to some estimates, India alone holds significant gas hydrate reserves in its continental shelf regions, which could play a key role in future energy security.

Gas Hydrates as an Energy Resource

Gas hydrates are gaining global attention as a potential energy source, as they are believed to contain vast amounts of methane, which could serve as an alternative to conventional natural gas.

Why Are Gas Hydrates Important?

- Abundant Supply – Gas hydrate deposits are estimated to contain twice as much carbon as all fossil fuel reserves combined.

- Potential to Meet Future Energy Demands – If extraction challenges are overcome, gas hydrates could serve as a long-term energy security solution.

- Cleaner Than Coal – Methane from hydrates burns cleaner than coal, emitting less CO₂ per unit of energy.

- Global Energy Revolution – Countries like India, Japan, the US, China, and Canada are investing heavily in gas hydrate research and extraction.

Challenges in Extraction and Utilization

While gas hydrates hold great promise, several technical and environmental challenges must be addressed:

- Extraction Difficulties – Unlike conventional natural gas, hydrates exist as solids and require advanced extraction techniques (such as depressurization or CO₂ swapping).

- Methane Release Risks – If improperly extracted, hydrates could release large amounts of methane, a greenhouse gas 25 times more potent than CO₂.

- Geological Instability – Disturbing hydrate-rich sediments could lead to underwater landslides and tsunamis.

- High Costs and Energy Intensity – Developing efficient, cost-effective technologies for hydrate extraction remains a challenge.

Extraction Technologies under Development

Scientists and engineers are working on several methods to safely and efficiently extract methane from gas hydrates:

1. Depressurization Method

By reducing the pressure around hydrate deposits, methane gas is released from the crystalline structure and can be collected for use.

2. Thermal Stimulation Method

Hydrates are heated to break their structure, releasing methane gas.

3. Chemical Injection (CO₂ Swapping)

Injecting CO₂ into hydrate formations replaces the trapped methane, allowing for its safe extraction while storing CO₂ underground—a potential carbon sequestration strategy.

Countries like Japan, the US, and India are leading pilot projects to test these methods in real-world conditions.

Global Gas Hydrate Reserves and India’s Potential

Estimated Global Gas Hydrate Reserves:

The total global methane hydrate reserves are estimated to be between 500 to 10,000 trillion cubic meters (tcm), which is far greater than all known conventional natural gas reserves.

India’s Potential:

India has significant gas hydrate deposits along its eastern and western coasts, including:

- Krishna-Godavari (KG) Basin

- Mahanadi Basin

- Andaman Sea

- Kerala-Konkan Basin

The Indian government, through agencies like the National Gas Hydrate Program (NGHP), is actively researching the commercial viability of these deposits.

Future Prospects: Is Gas Hydrate the Next Energy Revolution?

The future of gas hydrates as an energy source depends on overcoming technological, economic, and environmental barriers. Japan, India, China, the USA, and South Korea are investing in research to make gas hydrate extraction feasible within the next few decades.

Key Developments to Watch:

- Pilot projects in India’s Krishna-Godavari Basin.

- Japan’s success in offshore hydrate extraction (2017).

- Advances in CO₂-methane exchange technology for sustainable extraction.