Plastic Pollution, Solid, Hazardous and E-Waste

Plastic Pollution:

- Plastic pollution refers to the accumulation of plastic objects, microplastics, and synthetic polymers in the Earth’s environment that cause serious harm to wildlife, natural ecosystems, and human health. Plastics are non-biodegradable—meaning they persist in the environment for hundreds to thousands of years—breaking down into smaller particles but never truly decomposing.

The Global Scale of Plastic Pollution

Plastic production and waste have skyrocketed over the past few decades due to the increased reliance on single-use plastics and the durability and low cost of plastic materials. According to global estimates:

- Over 270 million metric tons of plastic are produced each year.

- Approximately 275 million metric tons of plastic waste are generated annually worldwide—more plastic is discarded than produced, due to leftover stockpiles and low recycling efficiency.

- Between 8 to 12 million metric tons of plastic waste enter the oceans every year, carried by rivers, wind, or improper waste disposal systems.

This relentless influx of plastic waste poses a growing threat to marine biodiversity, coastal environments, and the global food chain.

Microplastics, Microbeads & Nanoplastics:

Microplastics:

- Microplastics are defined as plastic fragments measuring less than 5 mm in length, yet exceeding 1 micrometer.

- These particles are often smaller than the smallest grains of sand and are only a fraction of the diameter of a human hair.

- They originate from a variety of sources, primarily through the degradation of larger plastic items.

- These microplastics are incorporated into a range of products, including cosmetics, personal care items, industrial cleaning agents, microfibers found in textiles, and virgin resin pellets utilized in the production of plastics.

- Numerous studies have confirmed the existence of microplastics in groundwater.

- One particular study estimated that the average individual consumes approximately 50,000 microplastic particles through food annually.

- The effects on small marine organisms are particularly concerning, as their ingestion leads to starvation and disrupts the marine food chain.

Microbeads:

- Microbeads, defined as plastic particles ranging from greater than 0.1 µm to less than 5 mm, are minuscule components incorporated into various health and beauty products, including certain cleansers and toothpaste (often referred to as cooling crystals).

- Nonetheless, a significant source of microbead pollution stems not from these intentionally produced microbeads, but rather from conventional plastic waste, of which 90% is not subjected to recycling.

The World Health Organization (WHO) has released its initial report regarding the impact of microplastics on human health, concluding that the concentration of microplastics found in drinking water does not currently pose a health risk to humans.

According to the WHO, microplastics exceeding 150 micrometers in size are unlikely to be absorbed by the human body; however, there is a greater potential for the absorption of much smaller microplastic particles, specifically those at the nanoscale.

Microplastics Detected in Human Blood:

- In a groundbreaking discovery, microplastic contamination has been identified in human blood for the first time. Analysis of blood samples revealed the presence of PET plastic, polystyrene, and polyethylene.

- These particles have the potential to circulate throughout the body and may become trapped in various organs.

- Research indicates that microplastics can adhere to the outer membranes of red blood cells, potentially impairing their oxygen transport capacity. Additionally, these particles have been detected in the placentas of expectant mothers.

Nano plastics:

Nano plastics refer to minuscule plastic particles that measure less than 1,000 nanometers (1 nm equals one billionth of a meter). These particles are capable of traversing physiological barriers and infiltrating living organisms.

- Primary nano plastics: These are deliberately manufactured for use in a range of products, including cosmetics, laundry detergents, and applications in research and diagnostics.

- Secondary nano plastics: These arise in the environment, particularly in aquatic ecosystems such as rivers and oceans, through the degradation of larger plastic debris.

Nano plastics in the Human Food Chain:

- Nano plastics have the ability to ascend the human food chain, affecting various organisms including plants, insects, and fish.

- Research has shown that nano plastics present in the soil are absorbed by plant roots and subsequently accumulate in their leaves.

- In both fish and mammals, the liver exhibits the highest concentration of nano plastics, suggesting that this organ serves as the main target tissue in vertebrates.

Major Plastics in Use:

Polyethylene Terephthalate (PET Plastic):

- PET (polyethylene terephthalate), the chemical name for polyester. It is a clear, strong, lightweight plastic widely used for packaging foods and beverages, especially convenience-sized soft drinks, juices, water, cook ing oils, etc.

- PET is entirely recyclable. They can easily be identified by the #1 in the triangular “chasing arrows” code, which is usually moulded into the bottom or side of the container. No other plastic carries the #1 code.

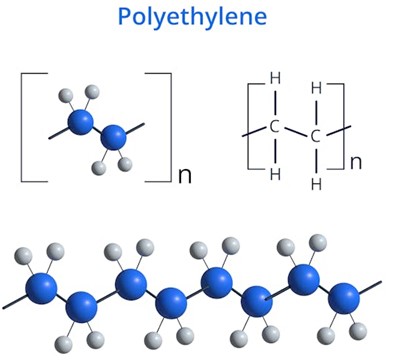

Polyethylene (PE):

- Polyethylene is the most widely utilized plastic today, synthesized through the polymerization of ethylene. Ethylene (C2H4) is a gaseous hydrocarbon that is predominantly generated from the cracking of ethane, a major component of natural gas.

- As a polymer, polyethylene is primarily employed in packaging applications, including plastic bags, films, geomembranes, and various containers such as bottles. While it exhibits low strength, hardness, and rigidity, it possesses high ductility, impact resistance, and low friction properties.

- Polyethylene is not easily biodegradable, leading to its accumulation in the environment. Nevertheless, certain bacterial species have the capability to degrade polyethylene. It is commonly abbreviated as “PE.”

Polystyrene:

- Polystyrene is a synthetic polymer derived from the aromatic hydrocarbon monomer styrene. This rigid and adaptable plastic is utilized in the production of a wide range of consumer goods. Its clarity makes it particularly suitable for applications such as food packaging and laboratory equipment.

- When blended with different colorants, additives, or other types of plastics, polystyrene is employed in the manufacturing of appliances, electronic devices, automotive components, toys, and plant pots.

Effects of Plastic Waste:

Effects on Health and Life:

- Numerous chemicals utilized in the production of plastic materials are recognized as carcinogens. These substances disrupt the endocrine system, leading to various disorders in development, reproduction, neurology, and immunity in both humans and wildlife.

- Dioxin, a highly carcinogenic toxin produced during the plastic manufacturing process, is one of the chemicals thought to be transmitted to infants through breast milk.

- The presence of plastic in the environment hampers the activity of soil microbes, as it can take decades or even centuries to break down. Terrestrial and aquatic animals often mistake plastic waste for food, resulting in ingestion and subsequent death.

Environmental Impact:

- The production and disposal of conventional plastics, which are derived from hazardous substances like benzene and vinyl chloride, pose a considerable environmental challenge.

- The initial emissions associated with plastic manufacturing include sulfur oxides, nitrous oxides, methanol, ethylene oxide, and volatile organic compounds (VOCs). The incineration of plastics, particularly polyvinyl chloride (PVC), releases harmful dioxins and furans (VOCs) into the atmosphere.

- Plastics have the potential to contaminate food and beverages as chemicals can leach into these products. Notable examples include polycarbonate, which releases bisphenol A—a substance linked to infertility, obesity, cardiovascular diseases, type II diabetes, and cancer; polystyrene, which leaches styrene; and polyvinyl chloride, which degrades into vinyl chloride.

- Improper disposal of plastic bags can obstruct drainage systems, impede soil permeability, and disrupt groundwater recharge processes.

Plastic Waste Management Rules, 2016:

- The Government of India has implemented the 2016 regulations, replacing the previous Plastic Waste (Management and Handling) Rules from 2011. These new rules have been expanded to include all villages, whereas the earlier regulations were applicable only to municipal areas.

- The 2016 regulations have raised the minimum thickness requirement for plastic carry bags from 40 microns to 50 microns and established a minimum thickness of 50 microns for plastic sheets.

- The use of plastic sachets for the storage, packaging, or sale of gutkha, tobacco, or pan masala is now prohibited.

Extended Producer Responsibility (EPR):

- EPR assigns accountability to producers, generators, and brand owners regarding waste management and collection systems.

- The collection of fees for managing plastic waste is facilitated through the pre-registration of producers, importers of plastic carry bags and multilayered packaging, as well as vendors who sell these items, in order to establish an effective waste management system.

Responsibility:

- Local authorities are tasked with the establishment, implementation, and coordination of the waste management system, as well as carrying out related functions.

- Retailers and street vendors are prohibited from selling or offering goods in plastic sheets or multilayered packaging; failure to comply will result in penalties.

Reuse of Plastic Waste:

- Investigating potential applications for repurposing plastic, including road construction, conversion of waste to oil, and waste-to-energy processes, which will improve plastic recycling efforts.

- Gradually eliminating non-recyclable multilayered plastics.

2018 Amendment:

- The revised regulations specify that the phase-out of Multilayered Plastic (MLP) applies solely to those MLPs that are deemed “non-recyclable, non-energy recoverable, or lacking alternative uses.”

- Additionally, the updated rules mandate the Central Pollution Control Board (CPCB) to develop an automated central registration system for the registration of producers, importers, and brand owners.

- Furthermore, Rule 15, which addressed the explicit pricing of carry bags as outlined in the 2016 regulations, has been removed.

2021 Proposed Regulations:

- The proposed regulations will broaden the scope to include brand owners and plastic waste processors, such as recyclers and co-processors.

- The draft suggests prohibiting certain single-use plastics starting January 1, 2022, and increasing the minimum thickness of carry bags made from virgin plastic from 50 microns to 120 microns.

Plastic Waste Management Amendment Rules 2021:

- The Ministry of Environment, Forest and Climate Change (MoEF) issued the 2021 regulations, which ban specific single-use plastic items characterized by low utility and high potential for littering, effective from July 2022.

- The minimum thickness for plastic carry bags was raised from 50 microns to 75 microns as of September 30, 2021, and will further increase to 120 microns starting December 31, 2022.

- The guidelines for Extended Producer Responsibility (EPR) have been given legal status.

- Plastic packaging waste that is not prohibited must be collected and managed under the Extended Producer Responsibility framework, which involves producers, importers, and brand owners (PIBO), in accordance with the 2016 regulations.

- The MoEF has established a national task force to coordinate efforts aimed at eliminating the specified single-use plastic items and ensuring the effective implementation of the Plastic Waste Management Rules of 2016. Additionally, states and union territories have been instructed to form a Special Task Force for this purpose.

Prohibited Plastics:

In compliance with regulations, the Central Pollution Control Board (CPCB) has released a list of single-use plastic products that will be entirely prohibited by the conclusion of June 2022.

- Earbud, balloon, candy, and ice cream plastic sticks.

- Plastic utensils, including plates, cups, glasses, forks, spoons, knives, and straws.

- Plastic films used for packaging or wrapping sweet boxes, invitation cards, and cigarette packets.

- Additional items: polystyrene (thermocol) used for decorative purposes, PVC banners with a thickness of less than 100 microns, and plastic stirrers.

NITI Aayog’s Report on Alternatives to Plastics:

NITI Aayog advocates for a waste reduction initiative in its publication titled ‘Alternative Products and Technologies to Plastics and their Applications’.

Key Findings from NITI Aayog’s Report:

- India generates 3.47 million tons of plastic waste annually.

- The per capita waste has increased from 700 grams to 2,500 grams in the past five years.

- The states with the highest per capita plastic waste generation are Goa, Delhi, and Kerala.

- Conversely, the states with the lowest per capita plastic waste generation include Nagaland, Sikkim, and Tripura.

- India manages to collect only 60% of its plastic waste, leaving 40% to enter the environment uncollected.

- On a global scale, 97-99% of plastics are produced from fossil fuel sources, while the remaining portion is derived from bio-based (plant) plastics.

Recommendations from the NITI Aayog Report include the following:

- Enhance waste reduction efforts through the implementation of Extended Producer Responsibility (EPR), effective labeling, and the systematic collection of compostable and biodegradable plastics, which are either plant-based or fossil fuel-derived plastics that do not produce toxic residues.

- Innovate additives that can transform biodegradable plastics into polyolefins, a category of thermoplastics that can be shaped through heat, including polypropylene, which is commonly used for a variety of plastic products, and polyethylene, the most widely utilized plastic.

- Promote the use of bio-plastics, derived from organic materials such as vegetable oils and starches, as a sustainable alternative to conventional plastics.

- Foster greater transparency in reporting waste generation, collection, recycling, and scientific disposal practices to enhance accountability and combat Greenwashing, which involves misleading claims about the environmental benefits of a company’s products.

Alternatives to Plastics:

- Glass: Considered the safest option for food and beverage packaging, glass is cost-effective, durable, and fully recyclable.

- Bagasse: This material is derived from the pulp of sugarcane or beets, making it compostable and environmentally friendly.

- Bioplastics: These are plastics made from plant materials, commonly utilized in food packaging applications.

- Natural textiles: Examples include materials such as cotton, wool, and hemp.

- Edible seaweed cups: Seaweed can grow significantly faster than terrestrial plants, making it a sustainable option for cup production.

- Algae-blended ethylene-vinyl acetate: This innovative material converts air and water pollutants (such as ammonia, phosphates, and carbon dioxide) into protein-rich plant biomass.

- Compostable plastics: These are plastics derived from either plant sources or fossil fuels that decompose through biological processes, resulting in carbon dioxide, water, inorganic compounds, and biomass without leaving harmful residues. An example is BASF’s Ecoflex.

Plastic waste in road construction:

- Polyblend is a finely processed powder derived from recycled and modified plastic waste. This material can be utilized in the production of fabrics and can also be combined with bitumen, the substance employed in road surfacing.

- The incorporation of Polyblend improves the water-repellent characteristics of bitumen and contributes to extending the lifespan of roads by up to three times.

Solid Wastes:

Solid waste encompasses a variety of discarded solid materials, including refuse, construction debris, sludge from wastewater treatment facilities, and other waste products. This waste can originate from various sources, such as industrial, commercial, mining, and agricultural activities, as well as from residential and public endeavors. Municipal solid waste, commonly referred to as trash or garbage, is a specific category of solid waste that includes everyday items such as paper, food scraps, plastics, glass, metals, rubber, leather, textiles, and more, which are disposed of by the general public.

Sources of Solid Wastes:

Industrial Solid Wastes:

Industrial solid waste includes various by-products from different sectors:

- Thermal power plants generate coal ash or fly ash, which enhances the durability of concrete used in road construction.

- Integrated iron and steel mills produce blast furnace slag, a material suitable for incorporation into Portland cement concrete, as well as for use in road and railway construction and soil conditioning.

- Non-ferrous metal industries, such as those dealing with aluminum, copper, and zinc, create red mud, which can serve as a construction material in bricks, lightweight aggregates, and roofing tiles.

- The sugar industry produces press mud, which can function as a soil conditioner and fertilizer.

- Pulp and paper manufacturing generates lime mud, which is applicable in the production of bricks, cement, wastewater treatment, and improving agricultural soils.

- Fertilizer and related industries produce gypsum, which is effective in mitigating soil alkalinity and is also utilized in Portland cement and plaster of Paris (POP).

Residential and Commercial Waste:

Waste generated from residential and commercial establishments encompasses a variety of materials, including organic food waste, plastics, paper products, glass, leather, and household items such as electronics, tires, batteries, discarded mattresses, used oil, wood, and cardboard.

Construction and Demolition Locations:

Construction sites encompass areas designated for the erection of new buildings and roads, as well as sites for road repairs, building renovations, and demolitions. These activities generate various solid wastes, including materials such as steel, concrete, wood, plastics, rubber, copper wiring, soil, and glass.

Bio-Medical Waste:

This term encompasses solid waste materials, including syringes, bandages, gloves, pharmaceuticals, plastics, and chemicals, generated from hospitals, biomedical devices, and chemical production facilities.

Management and Disposal of Solid Waste:

- The management of solid waste involves the collection and treatment of solid materials, as well as providing options for recycling items that should not be discarded in regular trash.

- As stipulated in the 12th Schedule of the 74th Constitution Amendment Act of 1992, urban local bodies (ULBs) are tasked with maintaining cleanliness in urban areas.

- Nevertheless, many ULBs face significant challenges due to insufficient infrastructure, limited institutional capacity, financial limitations, and a lack of political commitment.

Open dumps:

- Open dumps are defined as exposed locations designated for the disposal of various types of solid waste.

- This waste remains untreated, unprotected, and unsorted, creating an environment conducive to the proliferation of pests such as flies and rats, which can transmit diseases.

- Additionally, rainwater runoff from these dumps poses a risk of contaminating adjacent land and water sources.

Landfills:

- A landfill is an excavated area in the ground where waste is deposited. Daily, the accumulated refuse is covered with soil to inhibit the proliferation of pests such as flies and rats. Once the landfill reaches capacity, it is sealed with a substantial layer of earth, allowing for potential redevelopment into spaces like parking lots or parks.

- Various types of waste are disposed of in landfills, and as water permeates through the waste, it becomes contaminated, leading to pollution of the surrounding environment. This process, where contaminants leach into groundwater and soil, is referred to as leaching.

- Furthermore, landfills are not a sustainable solution to waste management, particularly in urban areas where waste generation has surged dramatically, resulting in these sites becoming towering heaps of refuse. A notable example is the garbage mountain at the Ghazipur landfill in Delhi.

Sanitary landfills:

- Open burning diminishes the amount of waste, but it typically does not result in complete combustion.

- Sanitary landfills were introduced as an alternative to open-burning dumps and conventional landfills.

- They are designed to be more hygienic and systematically address the issue of leachate. These landfills are lined with impermeable materials, including plastics and clay, and are constructed on impermeable soil.

- Nevertheless, the establishment of a sanitary landfill involves significant financial investment.

Incineration Facilities:

- Incineration refers to the method of combusting waste in substantial furnaces at elevated temperatures.

- Within these facilities, recyclable materials are separated from non-recyclable waste, which is then incinerated.

- This process is not environmentally friendly, as it generates significant amounts of hazardous ash and contributes to air and water pollution.

- Currently, incineration is considered a last option and is primarily employed for the disposal of infectious waste.

Pyrolysis:

- Pyrolysis refers to the thermal decomposition of materials in an oxygen-free environment or within a regulated oxygen atmosphere.

- This method serves as an alternative to incineration.

- The pyrolysis of carbon-rich waste materials, such as firewood, coconut husks, palm residues, corn cobs, cashew shells, rice husks, paddy straw, and sawdust, produces charcoal along with various byproducts, including tar, methanol, acetic acid, acetone, and gaseous fuels.

Plasma gasification:

- Plasma gasification is a high-temperature thermal process that employs electricity and plasma technology (without combustion) to transform organic materials into syngas, which consists of hydrogen and carbon monoxide. The inorganic components are transformed into slag, resulting in solid waste.

- This method serves as a more environmentally friendly option compared to landfilling, significantly decreasing or completely removing toxicity and preventing the disposal of large quantities of waste in landfills.

Composting:

- Composting is a natural biological process wherein microorganisms, predominantly fungi and bacteria, break down biodegradable organic materials into humus-like substances in an oxygen-rich environment.

- The resulting product, resembling soil, is rich in carbon and nitrogen, making it an exceptional medium for plant growth.

- Additionally, compost enhances the soil’s capacity to retain water and facilitates easier cultivation, while also improving the soil’s ability to hold essential nutrients for plants.

Vermiculture:

This technique involves the introduction of earthworms into the compost. These worms decompose the organic waste, and their excretions significantly enhance the nutrient content of the compost.

Biomining for Recycling:

- Biomining refers to the process of obtaining metals such as copper, uranium, nickel, and gold from ores and solid waste materials, primarily through the use of prokaryotic organisms, including bacteria, fungi, or plants.

- These microorganisms release various organic compounds that facilitate the bioleaching of metals from the ores and waste products.

Waste-to-Energy (WTE) Facility:

- The Waste-to-Energy process involves the conversion of waste into electricity and/or heat. This begins with the separation of biodegradable (wet) waste from dry waste at the point of origin.

- Local governments can utilize wet waste to create compost and biogas through biomethanation facilities. The dry waste, after extracting recyclable materials, is directed to WTE facilities.

- The inorganic component of dry waste is transformed into Refuse Derived Fuel (RDF), which has a calorific value of 2,500 kJ/kg and can be incinerated to generate electricity.

- RDF serves as a renewable energy source, helping to prevent waste from being disposed of in landfills.

Challenges Related to Waste-to-Energy Plants:

- Operational costs are elevated due to India’s reliance on foreign technology.

- Waste Composition: Waste-to-Energy (WTE) facilities necessitate fine inorganic materials with moisture content below 5% and soil content also under 5%. In contrast, Indian Municipal Solid Waste typically contains 15%-20% moisture and inert materials.

- Source Segregation: The lack of source segregation in urban areas necessitates additional sieving of collected waste, leading to increased expenses.

- Low Calorific Value for Energy Production: The presence of silt and soil particles can diminish the calorific value of the waste.

- Power Tariff: WTE plants acquire electricity at a tariff of approximately ₹7-8 per kWh, which is significantly higher than the ₹3-4 per kWh cost associated with coal and other energy sources.

Measures to Manage Solid Waste:

Solid Waste Management Rules (2016):

- These regulations supersede the Municipal Solid Wastes (Management and Handling) Rules of 2000.

- The current rules now apply not only to municipal areas but also to urban agglomerations, designated industrial townships, regions managed by Indian Railways, airports, defense establishments, and pilgrimage sites.

New responsibilities have been assigned to waste generators, requiring them to sort their waste into three categories prior to its collection:

1) Wet (Biodegradable)

2) Dry (including plastic, paper, metal, wood, etc.)

3) Domestic hazardous waste (such as diapers, sanitary napkins, containers for cleaning products, mosquito repellents, etc.)

Source Segregation of Waste:

- The practice of source segregation of waste has been mandated to transform waste into resources through recovery, reuse, and recycling.

- For events or gatherings exceeding 100 attendees, the organizer is responsible for ensuring that waste is segregated at the source and that the separated waste is delivered to a waste collection agency.

- Hotels and restaurants are also obligated to separate biodegradable waste and establish a collection system to facilitate the composting or biomethanation of food waste.

- All resident welfare associations, market associations, and gated communities covering an area greater than 5,000 square meters must implement source segregation of waste. They are required to provide recyclable materials to authorized collectors and recyclers or to the urban local authority.

Collect Back Initiative for Packaging Waste:

Manufacturers and brand owners who distribute or promote their products in non-biodegradable packaging materials are required to implement a system for the retrieval of packaging waste resulting from their production activities.

User Fees for Waste Management:

- Local government entities will impose user fees on bulk waste generators for the collection, disposal, and processing of waste.

- According to established regulations, waste generators are required to pay a “User Fee” to the waste collector, as well as a “Spot Fine” for offenses such as littering and failure to segregate waste. The amount of these fees will be determined by the respective local authorities.

Waste Management and Treatment:

- Biodegradable waste must be managed and eliminated via composting or biomethanation methods.

- Regulations require the bioremediation or capping of outdated and neglected landfill sites within a five-year period. Local authorities are obligated to establish waste processing facilities within this designated timeframe.

Advancement of Waste-to-Energy Initiatives:

- Industrial facilities located within a 100 km radius of a Refuse-Derived Fuel (RDF) Plant that utilizes solid waste are required to substitute a minimum of 5 percent of their fuel needs with the RDF generated.

- The Ministry of New and Renewable Energy should support the development of infrastructure for Waste-to-Energy facilities and offer suitable subsidies or incentives to promote these plants.

Revision of Parameters:

- The landfill location must be situated at least 100 meters from a river, 200 meters from a pond, 500 meters from highways, residential areas, public parks, and water supply wells, and 20 kilometers from airports or airbases.

- The emission standards for dioxins, furans, particulate matter, and other pollutants have been thoroughly revised.

- The standards for compost have been updated to comply with the Fertilizer Control Order.

Encouraging the Adoption of Compost:

- The Ministry of Chemicals and Fertilizers ought to offer support for market development concerning city compost.

- The Ministry of Agriculture should allow for greater flexibility within the Fertilizer Control Order to facilitate the production and distribution of compost, as well as to promote its application in agricultural practices.

Establishment of the Central Monitoring Committee:

A Central Monitoring Committee, chaired by the Secretary of the Ministry of Environment and Forests (MoEF), will be responsible for overseeing the enforcement of the regulations.

Additional features include:

- The state government will facilitate the transition of rag pickers from the informal sector into the formal economy.

- There will be a strict policy against the disposal of solid waste through throwing or incineration in public areas, including streets, open spaces, drainage systems, or water bodies.

- Manufacturers and brand owners of sanitary napkins will be held accountable for promoting awareness regarding the proper disposal methods for such waste by consumers.

- Suitable land for sanitary landfills will be identified in hilly regions, with construction planned in flat areas within a 25-kilometer radius.

Bio-Medical Waste (Management and Handling) Rules, 2016:

The Bio-Medical Waste Management Rules of 2016 represent an enhancement of the regulations established in 1998. This category of waste includes anatomical waste from humans and animals, as well as medical instruments such as needles utilized in healthcare settings, including hospitals, laboratories, and immunization programs.

Key Aspects of the BMW Management Rules, 2016:

- Chlorinated plastic bags, gloves, and blood bags are to be phased out within a two-year timeframe.

- Laboratory waste, microbiological waste, and blood samples must undergo pre-treatment through on-site sterilization.

- A bar-code system is to be implemented for bags or containers that hold bio-medical waste designated for disposal.

- The classification of bio-medical waste has been reduced from ten categories to four to enhance source segregation.

- The State Government is responsible for providing land for the establishment of common facilities for the treatment and disposal of bio-medical waste.

- No entity shall set up an on-site treatment and disposal facility if a service is available within a seventy-five-kilometre radius.

- Operators of common bio-medical waste treatment and disposal facilities are required to ensure the prompt collection of bio-medical waste from healthcare facilities (HCFs).

- The regulations will also apply to vaccination camps, blood donation camps, and similar events.

Procedure to be followed:

- Hospitals are required to establish effective disposal mechanisms, either independently or by utilizing shared biomedical waste treatment and disposal facilities.

- Hospitals that serve 1,000 or more patients each month must secure the necessary authorization and categorize biomedical waste according to the regulations. For instance, items such as syringes, needles, and blood-soaked bandages should be disposed of in a red bag or bin, designated for incineration. Any materials containing body fluids must also be incinerated.

Issues Related to Improper Biomedical Waste Management:

A significant portion, approximately 85%, of hospital waste is classified as non-hazardous, while the remaining 15% is deemed infectious or hazardous. The amalgamation of hazardous and non-hazardous waste renders the entire waste stream hazardous. This practice promotes the recycling of banned disposables and pharmaceuticals, which can exacerbate the transmission of infections. Additionally, it contributes to the emergence of resistant microorganisms, leading to antimicrobial resistance.

Other Measures:

Waste Minimization Circles (WMC):

- WMC supports small and medium-sized industrial clusters in reducing waste generated by their facilities. This initiative is facilitated by the World Bank and the National Productivity Council in New Delhi, with the Ministry of Environment and Forests serving as the coordinating body.

- The program seeks to fulfill the goals outlined in the Policy Statement for Abatement of Pollution (1992), which emphasizes the importance of educating the public about environmental hazards, the economic and health risks associated with resource depletion, and the true economic value of natural resources.

- Additionally, the policy acknowledges the contributions of citizens and non-governmental organizations in environmental oversight, thereby empowering them to enhance the existing regulatory framework.

Composite Waste Management Index: 2.0:

- Released by NITI Aayog in 2019, this index aims to motivate states and Union Territories (UTs) to utilize water resources more efficiently and effectively. It offers valuable insights for both state governments and relevant central ministries and departments.

- Rankings: Gujarat secured the top position among states, followed by Andhra Pradesh. Puducherry was recognized as the leading UT.

Lakshya Zero Dumpsite:

The Swachh Bharat Mission-Urban 2.0 (SBM-U 2.0) was initiated in 2021, aiming to establish Garbage Free Cities by the year 2026. In alignment with this objective, the Ministry of Housing and Urban Affairs introduced the Lakshya Zero Dumpsite initiative, which seeks to address the remediation of 16 crore metric tons (MT) of historical waste located on approximately 15,000 acres of urban land.

Hazardous Waste:

A hazardous substance is defined as any material that is present in or released into the environment and poses significant risks to public health and the well-being of the environment. Such substances may demonstrate one or more of the following properties: toxicity, ignitability, corrosivity, or reactivity (including explosiveness). Consequently, any waste that contains hazardous substances is classified as hazardous waste.

Persistent Organic Pollutants (POPs):

- POPs are characterized as “chemical substances that remain in the environment for extended periods, accumulate in the food chain, and present risks of negative impacts on human health and the ecosystem.”

- These chemicals are of international concern due to their capacity for long-distance transport and their tendency to bioaccumulate and biomagnify within ecological systems.

The most frequently identified POPs include organochlorine pesticides such as:

- Dichlorodiphenyltrichloroethane (DDT),

- Endosulfan, Chlordane, Endrin, and Heptachlor (previously utilized as pesticides),

- Hexachlorobenzene (a fungicide),

- Polychlorinated biphenyls (PCBs—released during the incineration of plastics and electrical components; they are resistant to extreme temperatures and pressures, making them prevalent in electrical devices like capacitors and transformers),

- Dioxins (toxic by-products generated from the combustion of organic materials), among others.

DDT was extensively employed several decades ago as a potent pesticide and insecticide. However, it was later recognized as a POP, leading to its gradual elimination in all developed nations and in the majority of developing countries. DDT is prohibited for agricultural purposes in India; nonetheless, it remains in use for fumigating mosquitoes, which are vectors of disease, in various regions across the country.

Chlorinated Hydrocarbons (Organochlorides):

Chlorinated Hydrocarbons (CHCs or Perfluoro Chlorides) are persistent organic pollutants characterized by the substitution of one or more hydrogen atoms with chlorine atoms. Examples include DDT (dichlorodiphenyl trichloroethane), endosulfan, chloroform, and carbon tetrachloride, among others.

Applications of Chlorinated Hydrocarbons:

- Chlorinated hydrocarbons (CHCs) play a significant role in the production of polyvinyl chloride, a plastic polymer commonly utilized in the manufacturing of PVC pipes.

- Solvents such as chloroform, dichloromethane, dichloroethane, and trichloroethane are valuable due to their immiscibility with water, making them effective for cleaning purposes, including degreasing and dry cleaning. Additionally, compounds like DDT, heptachlor, and endosulfan have been employed as pesticides.

Effects of C hlorinated Hydrocarbons (CHC):

- DDT has been shown to accumulate within food chains, leading to a reduction in eggshell thickness in various bird species.

- In India, remnants of DDT spray applied over thirty years ago are still detectable on residential walls.

- Residual DDT continues to be present in mammals worldwide, with particularly elevated concentrations observed in marine mammals in Arctic regions.

- The presence of persistent organic pollutants (POPs) has been identified in the breast milk of numerous mammals. In females, the concentration tends to be lower due to the transfer of these compounds to their young during lactation.

Perfluoroalkyl Acids (PFAAs):

- Perfluoroalkyl acids (PFAAs) are classified as emerging persistent organic pollutants (POPs) and are distinct from perfluoro chlorides, which are organochlorine compounds. PFAAs are utilized in the production of water- and stain-repellent coatings for textiles, leather, upholstery, and carpets, as well as in oil-resistant coatings for food-contact paper products, electroplating, and electronic etching applications.

- These substances are characterized by their longevity in the environment and are significant pollutants that accumulate in glaciers. PFAAs resist biodegradation and can traverse various organisms and ecosystems.

- As glaciers melt, they release PFAAs into surrounding lakes, which may result in the bioaccumulation of these compounds in fish populations. Consuming fish contaminated with PFAAs poses serious health risks to humans.

- Notably, Himalayan glaciers may exhibit higher concentrations of PFAAs compared to glaciers elsewhere in the world, largely due to their proximity to South Asian countries, which are among the most polluted regions globally.

Endosulfan:

It is classified as an organochlorine insecticide and is recognized as a persistent organic pollutant (POP). Its primary application is in agriculture as an insecticide, and it is additionally utilized as a preservative for wood.

Prohibition of Endosulfan:

- India has historically been one of the largest producers and consumers of endosulfan. The harmful effects of this pesticide gained attention in 2001, leading to its prohibition in Kerala.

- In 2011, the Supreme Court of India imposed a ban on the production, distribution, and utilization of endosulfan throughout the country, instructing the Kerala government to allocate Rs 500 crores for the compensation of over 5,000 affected individuals.

- On a global scale, the use of endosulfan is prohibited under the Stockholm Convention on Persistent Organic Pollutants. However, under pressure from pesticide manufacturers, India requested a 10-year exemption from the ban and committed to phasing out endosulfan by 2017.

Hazardous Impacts of Endosulfan:

- Endosulfan is extremely toxic and possesses a significant capacity for bioaccumulation, meaning it remains within the organism.

- It adversely affects both genetic and endocrine systems.

- As an endocrine disruptor, it amplifies the effects of estrogens, leading to reproductive and developmental harm in both animals and humans.

- It is neurotoxic, compromising the integrity of nerve cells.

Regulation of Persistent Organic Pollutants Rules, 2018:

The Ministry of Environment, Forest and Climate Change (MoEF) has established the ‘Regulation of Persistent Organic Pollutants Rules’ in 2018, pursuant to the Environment (Protection) Act of 1986.

These regulations prohibit the production, commerce, utilization, importation, and exportation of seven specific chemicals, which include:

- Chlordecone,

- Hexabromobiphenyl,

- Hexabromodiphenyl ether and HeptaBromodiphenyl Ether (Commercial octa-BDE),

- Tetrabromodiphenyl ether and Pentabromodiphenyl ether (Commercial penta-BDE),

- Pentachlorobenzene,

- Hexabromocyclododecane, and

- Hexachlorobutadiene.

The ratification of these rules will allow India to access financial resources from the Global Environment Facility (GEF).

Regulating Hazardous Waste:

Stockholm Convention on Persistent Organic Pollutants (POPs):

The Stockholm Convention on Persistent Organic Pollutants (POPs) is a global treaty established in 2004 aimed at the elimination or limitation of the production and utilization of POPs.

Significant Substances Listed:

- Aldrin: Employed as an insecticide.

- Heptachlor: Utilized as a termiticide, particularly in the treatment of structures and underground applications, including cable boxes.

- Hexachlorobenzene: Functioning as a chemical intermediate and a solvent for pesticides.

- Endrin: Primarily used as an agricultural insecticide on crops such as tobacco, apple trees, cotton, sugar cane, rice, cereals, and grains.

- Polychlorinated biphenyls (PCBs): Their commercial use is largely attributed to their chemical stability, low flammability, and advantageous physical properties, including electrical insulation; however, they are highly toxic.

- DDT: DDT is the most recognized among various chlorine-containing pesticides that were widely used during the 1940s and 1950s.

Basel Convention on Hazardous Waste:

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal is an international agreement that came into effect in 1992. As of 2018, there are 190 countries that are parties to this Convention. Although the United States has signed the Convention, it has yet to ratify it.

The objectives of the Basel Convention include:

- Limiting the transboundary movement of hazardous waste among nations.

- Preventing the export of hazardous waste from developed countries to less developed countries (LDCs).

- Reducing both the volume and toxicity of waste produced.

- Supporting LDCs in the environmentally sound management of the hazardous and other types of waste they generate.

Limitations of the Basel Convention: Toxic Colonialism Under the Guise of Recycling:

- The Basel Convention primarily aims to regulate the trade of hazardous waste rather than implementing a comprehensive ban on it.

- It establishes a notification and consent mechanism known as prior informed consent but does not prohibit the export of waste to any region, with the sole exception of Antarctica. Additionally, the convention fails to address the transportation of radioactive waste.

- Numerous waste traders disguise the shipment of hazardous materials as transfers to recycling facilities.

- The recycling process often involves dismantling electronic waste and shipbreaking, typically carried out by vulnerable and unprotected laborers.

- Moreover, waste generated by shipping companies—including decommissioned vessels, hazardous asbestos, and flammable gases and oils—often ends up on the shores of South Asia, leading to environmental pollution and serious occupational health risks.

- For instance, the Alang Ship Breaking Yard in Gujarat ranks among the largest ship-breaking facilities globally. In the 2021 Budget address, the Finance Minister announced plans to double the ship recycling capacity by 2024 and to attract additional vessels from Europe and Japan to India.

Basel Ban Amendment to the Basel Convention:

- There was a widespread belief that a total prohibition on the transportation of hazardous waste, including its export for recycling purposes, was essential. This sentiment culminated in the adoption of the Basel Ban Amendment in 1995, which was recognized as a significant milestone in the pursuit of global environmental justice.

- For the Basel Ban Amendment to be enacted as law, it required ratification by three-quarters of the parties to the Convention. It ultimately achieved international legal status in 2019 following Croatia’s ratification. This amendment will be incorporated as a new Article in the Convention and will take effect in 97 countries after a 90-day period.

- Several nations, including the United States, Canada, Japan, Australia, New Zealand, South Korea, Russia, India, Brazil, and Mexico, have yet to ratify the ban, which aims to halt the import and export of hazardous waste.

- The United States, which generates the highest amount of waste per capita, has consistently opposed the Ban Amendment, as it restricts the export of hazardous waste (including electronic waste) from a group of developed countries, primarily those in the OECD, to developing nations.

- The Basel Ban encompasses exports for all purposes, including recycling. Notably, India dominates the global ship recycling sector, holding over 30% of the market share.

Rotterdam Convention on Prior Informed Consent:

- The Rotterdam Convention on the Prior Informed Consent Procedure for Certain Hazardous Chemicals and Pesticides in International Trade is a multilateral agreement aimed at fostering collective responsibilities regarding the importation of hazardous substances.

- This convention encourages transparent information sharing and requires exporters of hazardous chemicals to implement appropriate labeling, ensure safe handling practices, and notify buyers of any existing restrictions or prohibitions.

- Countries that are parties to the convention have the authority to determine whether to permit or prohibit the importation of the chemicals specified in the treaty.

The collaborative meetings of the Basel, Rotterdam, and Stockholm Conventions took place in Geneva in 2021. These included:

- COP9 of the Stockholm Convention

- COP14 of the Basel Convention

- COP9 of the Rotterdam Convention

The overarching theme for these meetings was “Clean Planet, Healthy People: Sound Management of Chemicals and Waste.”

The Conference of the Parties (COP) to the Stockholm Convention made the decision to include “Dicofol” in Annex A without any exemptions. Additionally, “PFOA” was added to Annex A of the Stockholm Convention, albeit with certain exemptions.

Dicofol:

It is an organochlorine pesticide that shares a chemical relationship with Dichlorodiphenyltrichloroethane (DDT). Its applications are diverse, spanning both industrial and household uses, such as in non-stick cookware, food processing machinery, carpets, paper products, and paints.

Perfluorooctanoic acid (PFOA):

- Perfluorooctanoic acid (PFOA) is utilized in the production of Teflon, which is commonly found in non-stick cookware.

- PFOA has the ability to persist in both the environment and the human body for extended durations. It is classified as a carcinogen and is known to be toxic to the liver, as well as harmful to developmental and immune systems.

COP14 to the Basel Convention:

- The convention was revised to incorporate plastic waste within a legally binding framework.

- This amendment grants developing nations the authority to reject the importation of plastic waste from other countries, as plastic waste is now part of the Prior Informed Consent procedure.

- Although the United States and a few other nations have not ratified the agreement, they are still unable to export plastic waste to countries that have endorsed the accord.

- India has already enacted a total ban on the importation of solid plastic waste into its territory.

COP9 to the Rotterdam Convention:

The Rotterdam Convention has expanded its list of substances subject to mandatory Prior Informed Consent (PIC) procedures in international trade by including two new chemicals: acetochlor and hexabromocyclododecane (HBCD), along with phorate.

Hong Kong Convention on Ship Recycling:

- The Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, established in 2009, was created in collaboration with the International Labour Organization and the signatories of the Basel Convention.

- This Convention aims to tackle various challenges associated with ship recycling, particularly the presence of hazardous materials like asbestos and heavy metals in vessels designated for dismantling.

- Additionally, it seeks to improve the working conditions prevalent at numerous ship recycling sites around the globe.

Regulatory Measures by India:

Recycling of Ships Act, 2019:

This legislation aims to promote environmentally responsible ship recycling while ensuring the safety of workers in the shipbreaking yards. The Bill incorporates the Shipbreaking Code of 2013 and adheres to the stipulations outlined in the Hong Kong Convention.

Recycling:

- The legislation characterizes ship recycling as the process of deconstructing a vessel at a designated facility to reclaim its components and materials for future use, while also managing any hazardous materials generated during this process.

- Ships are permitted to be recycled solely at approved recycling facilities. Each recycling operator is required to implement sufficient measures for emergency readiness, as well as to ensure the safety and well-being of their workforce.

Criteria for Vessels:

Vessels must refrain from utilizing hazardous materials that are explicitly banned. The central government has the authority to grant exemptions for specific categories of vessels. This stipulation does not pertain to (i) any military ship and (ii) vessels with an internal capacity of under 500 tons.

National Authority:

- The National Authority is responsible for carrying out regular surveys to ensure compliance with established requirements.

- Every new ship owner is required to submit an application to the National Authority to receive a certificate detailing the inventory of hazardous materials.

- The Ship Recycler is obligated to develop a ship recycling plan, which must receive approval from the National Authority. Recycling of each ship will only proceed after securing written consent from the National Authority.

Advantages of the Legislation:

- A greater influx of international vessels will be directed to Indian shipyards for recycling purposes.

- The ship recycling industry is expected to enhance business prospects and create job opportunities.

- The value of ship recycling facilities in Alang (Gujarat), Mumbai Port, Kolkata Port, and Azhikkal (Kerala) will experience an increase.

- Approximately 10% of the nation’s secondary steel requirements can be sustainably fulfilled through the recycling of ships.

- Ship recycling operations will align with global standards of compliance.

Hazardous Wastes (Management and Handling) Rules, 2016:

This set of regulations introduces a novel classification that differentiates hazardous waste from other types of waste. The latter category encompasses materials such as waste tyres, paper waste, metal scrap, and used electronic devices, which are acknowledged as valuable resources for recycling and reuse.

Key Characteristics:

- The scope of the Rules has been broadened to encompass ‘Other Waste.’

- A hierarchy for waste management has been established, prioritizing prevention, minimization, reuse, recycling, recovery, co-processing, and safe disposal.

- The regulations promote the reduction of hazardous waste production while advocating for its recycling and reuse.

- They outline stringent regulations concerning the import, export, storage, and transportation of hazardous wastes.

Importation and Management of Hazardous Waste:

India prohibits the importation of hazardous waste for final disposal from any country. Consequently, hazardous waste can only be imported into India for purposes such as recycling, reuse, or other forms of utilization. The regulations outline the protocols for the import and export of hazardous waste to and from India.

Facility for the Treatment, Storage, and Disposal of Hazardous Wastes:

The regulations established in 2016 provide explicit guidelines for the creation of facilities dedicated to the treatment, storage, and disposal of hazardous wastes. Approval from the State Pollution Control Board (SPCB) is necessary for the facility’s design and layout.

Guidelines for the Packaging, Labelling, and Transportation of Hazardous and Other Wastes:

The Central Pollution Control Board (CPCB) offers comprehensive directives regarding the packaging and labelling of waste. When waste is to be transported to a disposal facility located in another state, the sender must obtain a ‘No Objection Certificate’ from the State Pollution Control Boards (SPCBs) of both the originating and receiving states.

Amendment of 2019:

The amendment was enacted with the aim of enhancing the “Ease of Doing Business” and promoting the “Make in India” initiative by streamlining the procedures outlined in the Rules. This effort also prioritizes the principles of sustainable development and seeks to minimize environmental impact.

Key Highlights:

- The importation of solid plastic waste has been banned across the country, including within Special Economic Zones (SEZ) and by Export Oriented Units (EOU).

- Silk waste exporters are now exempt from the requirement to obtain permission from the Ministry of Environment, Forest and Climate Change (MoEF).

- Defective electrical and electronic assemblies and components that are manufactured and exported from India can now be returned to the country without needing permission from MoEF.

- Industries that are not mandated to obtain consent under the Water (Prevention and Control of Pollution) Act of 1974 and the Air (Prevention and Control of Pollution) Act of 1981 are also exempt from authorization under the Hazardous and Other Wastes Rules of 2016.

Lack of Regulations for Cigarette Butt Disposal:

- Cigarette butts are primarily composed of cellulose acetate, which constitutes approximately 95% of their material, along with rayon. Currently, there is no available data regarding the toxicity of cellulose acetate, and it is known to remain in the environment for an extended period.

- The Ministry of Environment, Forest and Climate Change (MoEF) has indicated that cigarette butts are not classified as hazardous waste, while the Ministry of Health has asserted that they are not biodegradable. Consequently, the National Green Tribunal (NGT) has instructed the Central Pollution Control Board (CPCB) to establish guidelines for the proper disposal of cigarette and beedi butts.

Steel Scrap Recycling Policy:

- Steel is exceptionally suited for a circular economy due to its capacity for infinite use, reuse, and recycling. While iron ore serves as the primary raw material for steel production, scrap steel represents a vital secondary resource for the steel industry.

- The National Steel Policy (NSP) 2017 aims to establish a globally competitive steel sector by achieving a production capacity of 300 million tons per annum by 2030, with 35-40% of this capacity derived from the Electric Arc Furnace (EAF) method.

- Although scrap is predominantly utilized in the secondary steel sector, it also plays a significant role in the primary sector, where it constitutes approximately 15% of the charge mix in Basic Oxygen Furnaces (BOF). This incorporation enhances efficiency and reduces production costs and other operational requirements.

- Ensuring the availability of raw materials at competitive prices is crucial for the advancement of the steel industry and for meeting the NSP-2017 objectives. Consequently, securing an adequate supply of high-quality scrap is essential for the future development of both the EAF/Induction Furnace (IF) sector and the primary sector.

- The Ministry of Steel serves as the primary governmental body responsible for addressing all matters related to scrap.

Key Aspects of the National Steel Scrap Policy:

- This policy establishes a framework aimed at encouraging the development of metal scrapping facilities across India, focusing on the scientific processing and recycling of ferrous scrap sourced from various origins.

- It outlines the responsibilities associated with the establishment of collection, dismantling, and scrap processing centers, detailing the roles of aggregators as well as the obligations of the government, manufacturers, and scrap owners. Notably, the policy does not anticipate the government establishing scrap centers; instead, it positions the government as a facilitator to support the metal scrapping ecosystem within the country.

- The initiative to create scrap centers rests with entrepreneurs, who will make decisions based on commercial viability. These scrapping facilities will be approved and overseen by authorized agencies within the respective States and Union Territories. The policy does not propose any additional monitoring frameworks, thus alleviating any extra compliance requirements.

- The policy framework offers standardized guidelines for the collection, dismantling, and shredding processes, ensuring that these activities are conducted in an organized, safe, and environmentally responsible manner.

Scrap Categories:

- Home Scrap: This category includes scrap produced at various stages throughout the manufacturing process of steel and steel products within steel plants.

- New Scrap/Industrial Scrap: This type of scrap is generated during the downstream processing involved in the manufacturing and fabrication of steel products, including the production of automotive components, household appliances, machining, and the manufacture of tools and equipment.

- Old Scrap/Obsolete Scrap: This refers to steel that is discarded when steel products, such as end-of-life vehicles, appliances, machinery, buildings, bridges, ships, cans, and railway coaches and wagons, have reached the end of their useful life.

Objectives of the Policy:

- To encourage systematic and scientific practices for the collection, dismantling, and processing of end-of-life products that yield recyclable materials (including ferrous, nonferrous, and various non-metallic scraps). This initiative aims to enhance resource conservation, achieve energy efficiency, and establish an environmentally responsible management system for ferrous scrap.

- To develop a framework for the treatment of waste streams and by-products generated from dismantling and shredding operations, ensuring compliance with the Hazardous and Other Wastes (Management and Transboundary Movement) Rules, 2016.

- To advocate for the principles of the 6Rs—Reduce, Reuse, Recycle, Recover, Redesign, and Remanufacture—through the scientific management, processing, and disposal of all categories of recyclable materials, including non-ferrous scraps, at authorized centers and facilities.

Benefits of the Policy:

- Utilizing each ton of scrap metal results in the conservation of 1.1 tons of iron ore, 630 kilograms of coking coal, and 55 kilograms of limestone. This practice contributes to a reduction in water usage and greenhouse gas emissions by 40% and 58%, respectively.

- Globally, there is a growing trend to enhance steel production by prioritizing scrap as the main raw material, as recycling scrap not only preserves essential natural resources but also offers a variety of additional advantages.

Heavy Metals:

- Heavy metals, characterized by their relatively high density compared to water, are metallic elements that pose significant risks to the environment, humans, and other living organisms, even at minimal concentrations.

- These metals are largely resistant to biological degradation, leading to their bioaccumulation within organisms and biomagnification through the food chain, which presents the most severe threats to apex predators.

- Water-soluble heavy metals include arsenic, cadmium, lead, mercury, barium, chromium, platinum, palladium, and silver, with arsenic, cadmium, lead, and mercury being particularly dangerous.

- While natural water sources contain only trace amounts of these heavy metals, substantial levels of toxic metals are released into the environment through industrial emissions from metal smelting, the incineration of organic waste, automobile exhaust, and coal-fired power generation.

- Heavy metal poisoning, or toxicity, occurs when heavy metals infiltrate the human body, attaching to cells and disrupting the normal operation of organs. This condition can lead to permanent harm and may pose a serious risk to life in certain situations.

- Heavy metals can be transported over considerable distances from their original sources by wind, particularly when released as gases or fine particles.

- Eventually, precipitation cleanses the atmosphere of these metallic contaminants, depositing them onto land and into aquatic environments.

Lead:

- Primary Sources: mining operations, lead-acid batteries, recycling of battery scrap, quick-drying paints and pigments, fly ash, and plastic toys (which utilize lead to enhance plastic flexibility).

- Secondary Sources: food cans with lead solder, lip cosmetics, lead contamination in water (due to lead pipes), phased-out leaded petrol, glass (which incorporates lead during the manufacturing process), certain ayurvedic medicines, among others.

- E-waste Sources: rechargeable lead batteries, solar energy panels, transistors, lithium-ion batteries, PVC materials, solder used in printed circuit boards (PCBs), and glass panels and gaskets found in computer monitors, among others.

Lead Poisoning: In low-income countries, the recycling of lead-acid batteries significantly contributes to the incidence of lead poisoning among children.

Health Impacts:

- Lead is recognized as a carcinogenic substance that primarily affects the lungs and kidneys. Its detrimental effects extend to various organs, particularly in developing fetuses, where it can result in stillbirths and miscarriages.

- Additionally, lead exposure can lead to irreversible behavioral and neurological impairments, as well as other developmental issues in children.

- Lead can contaminate water and food supplies, leading to cumulative poisoning that may result in neurodegenerative disorders and impairments in the central nervous system.

- Exposure to lead during pregnancy can induce developmental reprogramming in the fetus, which may increase the likelihood of developing Alzheimer’s disease at an earlier age in later life.

Leaded Petrol: Global Prohibition and Achievements:

India’s Prohibition of Leaded Petrol:

- In the year 2000, India implemented a ban on leaded petrol to address the issues of air pollution and associated public health hazards.

- By 2011, the United Nations recognized the global elimination of leaded gasoline as a significant accomplishment in the effort to reduce lead contamination on a worldwide scale.

Toxic Metals in Ayurvedic Treatments:

Incorporation of Metals in Rasa Shastra:

- The Ayurvedic discipline known as Rasa Shastra utilizes various metals, including lead, mercury, copper, gold, iron, silver, tin, and zinc, for their alleged health benefits.

- These practices are contentious due to insufficient regulation and oversight, which have led to instances of toxic metal overdoses in some Ayurvedic products.

Health Risks Associated with Toxic Metals:

Concerns Regarding Toxicity:

- Excessive exposure to metals such as lead, mercury, and arsenic can result in serious health complications, including cognitive deficits and damage to vital organs.

- It is crucial to establish regulatory frameworks to guarantee the safety and effectiveness of traditional medicinal practices.

Alzheimer’s Disease and Cognitive Deterioration:

Comprehending Alzheimer’s Disease:

- Alzheimer’s disease stands as the primary cause of dementia, marked by memory impairment and a decline in problem-solving and learning capabilities.

- This progressive neurological disorder currently has no cure, underscoring the importance of early diagnosis and ongoing research into potential treatments.

Mercury:

- Elemental mercury exhibits a high surface tension, resulting in the formation of small, compact, spherical droplets upon its release into the environment.

- While these droplets remain stable, the elevated vapor pressure of mercury relative to other metals leads to its evaporation.

- In enclosed spaces, this can rapidly create an inhalation risk. In outdoor environments, elemental mercury vaporizes and disperses into the atmosphere.

- In aquatic ecosystems, indigenous microorganisms can convert mercury into methylmercury, an organometallic compound that poses a greater toxicity at lower concentrations than elemental mercury itself.

Sources:

- Natural: This category includes volcanic eruptions, fossil fuels, metal ores, and various other minerals.

- Anthropogenic: This encompasses the extraction and processing of metals such as copper, gold, lead, and zinc, the combustion of coal, the production of cement (derived from limestone and/or coal), and the manufacturing of caustic soda, among others.

- E-waste Sources: A wide range of electrical and electronic devices contain considerable amounts of mercury, including LCD screens, compact fluorescent lamps (CFLs), cathode ray tube (CRT) monitors, switches, printed circuit boards (which often use tin as an alloy), batteries, mercury thermometers, thermostats, sensors, medical devices, lamps, and mobile phones.

Health Impacts:

- Mercury is recognized for its potential to inflict significant and lasting harm to the central nervous system, lungs, and kidneys. It may also induce depression, suicidal thoughts, paralysis, Alzheimer’s disease, and impotence, among other health issues.

- Breathing in mercury vapors poses a greater risk than consuming it. Methylmercury and metallic mercury vapors are particularly detrimental, as these forms of mercury can more easily penetrate the brain.

- Continuous exposure can lead to irreversible damage to the nervous system, especially in children.

Methylmercury:

- Methylmercury is an extremely toxic variant of mercury. It is produced in the environment when bacteria interact with mercury present in water, soil, or vegetation.

- Common sources include compact fluorescent lamps (CFLs), batteries, and polyvinyl chloride (PVC) materials, among others.

- Health implications: Exposure to methylmercury, a neurotoxic substance, can result in significant harm to the brain and nervous system. The developing fetus is particularly susceptible to the effects of mercury exposure.

Minamata Convention:

- In the 1960s, Japan experienced widespread mercury poisoning, known as Minamata disease, which resulted from the consumption of fish contaminated with methylmercury from Minamata Bay (a substance that bioaccumulates and biomagnifies).

- Individuals affected by Minamata disease reported symptoms such as loss of sensation and numbness in their extremities. Many struggled to walk or run without falling, and they faced challenges with vision, hearing, and swallowing. A significant number of those affected succumbed to the illness.

Cadmium:

Sources:

- Primary Sources: extraction activities, particularly in zinc and copper mining, metallurgical processes, and electroplating sectors, among others.

- E-waste Sources: components such as solar panels, batteries, solder materials, alloys, switches, printed circuit boards (PCBs), computer batteries, cathode ray tube (CRT) monitors, surface-mount technology (SMT) chip resistors, infrared detectors, semiconductor chips, and UV stabilizers found in older PVC cables, among others.

Health Impacts:

- Cadmium, recognized as a carcinogen, can enter the human body through inhalation or consumption of aquatic organisms, such as fish. Its exposure is linked to hypertension, as well as damage to the liver and kidneys, and an increased risk of lung cancer.

- Prolonged exposure to cadmium can lead to Itai-itai disease, characterized by intense pain in the joints and spine, along with kidney impairment and bone softening.

- This condition was first documented in Japan in 1965 and was associated with cadmium pollution in water and rice, resulting from the discharge of waste from a zinc smelting facility.

Chromium:

- Sources: Hexavalent chromium (Chromium VI) serves as a corrosion inhibitor for untreated and galvanized steel plates, metal enclosures, and components in computers. It is also utilized in chrome tanning within the leather industry and acts as a decorative element or hardener for plastic materials, including polyvinyl chloride (PVC).

- Health effects: Exposure to chromium or chromium VI through inhalation can lead to liver and kidney damage, as well as respiratory issues such as asthmatic bronchitis and lung cancer. Additionally, Chromium VI has the potential to cause DNA damage.

Other Heavy Metals:

Metals like zinc, chromium, antimony, and tin can leach into food from inexpensive cooking utensils.

Arsenic:

It can be derived from various sources, including ores of copper, iron, and silver, as well as fly ash and liquid waste from fertilizer manufacturing. Additionally, it is found in semiconductors, diodes, microwave technology, light-emitting diodes (LEDs), and solar cells, among others.

Antimony:

- Antimony serves to enhance the hardness of various alloys. Additionally, antimony trioxide is utilized in the formulation of flame-retardant substances.

- Sources include a minor component in metal solders, lead alloys employed in batteries, and lead/copper/tin alloys used for bearings.

- Health implications: antimony trioxide is considered a potential carcinogen.

Tin:

- Sources: food items that are preserved and packaged in tin cans.

- Health effects: tin acts as an irritant, and an excessive intake of tin may lead to harm to the liver and kidneys.

Zic:

- Zinc is a vital nutrient present in various parts of the body, playing a crucial role in supporting the immune system and facilitating metabolic processes. It is also important for the healing of wounds and for maintaining the senses of taste and smell.

- Sources: Zinc can be obtained from mining activities, metal smelting processes (including those involving zinc, lead, and cadmium), fly ash, steel, brass, various alloys, as well as from both disposable and rechargeable batteries, and luminous materials, among others.

- Health implications: An excess of zinc can lead to skin irritation and may adversely affect the respiratory system.

Barium:

- Sources: It is primarily derived from the oil and gas sectors, where it is utilized in the production of drilling mud that facilitates the drilling process by lubricating the drill bit. Additionally, barium is found in products such as paint, tiles, and fireworks, where compounds like barium nitrate and barium chlorate are employed to produce green hues.

- E-waste Sources: Barium is present in various electronic waste items, including spark-plug electrodes, vacuum tubes (which serve as oxygen-removing agents), and compact fluorescent lamp (CFL) bulbs, which consist of a spiral-shaped tube made from tungsten and coated with barium, strontium, and calcium oxides. It is also found in the front panel of Cathode Ray Tubes (CRTs) in computers, where it functions to shield users from radiation exposure.

- Health effects: Exposure to barium can lead to a range of health issues, including nausea, cerebral edema, muscle weakness, arrhythmias, and paralysis, among other symptoms.

Beryllium:

- Sources in Electronic Waste: Printed circuit board (PCB) motherboards utilize a copper-beryllium alloy to enhance the strength of connectors while preserving electrical conductivity.

- Health Implications: Exposure to beryllium can lead to lung cancer, respiratory damage, and impaired wound healing, among other health issues.

Electronic Waste (E-Waste):

- Electronic waste, commonly referred to as e-waste, encompasses discarded and obsolete electrical and electronic equipment (EEE), including computers, home appliances, audio and video devices, and their associated peripherals.

- E-waste does not pose a hazard when it is stored securely, recycled using proper scientific methods, or transported—either in whole or in parts—through formal channels. Conversely, e-waste can be deemed hazardous if it is recycled or disposed of improperly.

E-Waste Source and Health Effects:

- Toners: Present in printer cartridges that contain both black and color toners; these substances can irritate the respiratory system, and carbon black is recognized as a carcinogen.

- Phosphor Additives: Found in the phosphor coatings of cathode ray tubes; these additives include hazardous heavy metals such as cadmium, zinc, and vanadium.

- PVC Plastics: Utilized in cables, computer casings, and moldings; when incinerated, they emit dioxins, which are known endocrine disruptors.

- Phthalates: Used to enhance the flexibility of plastics, particularly PVC; these compounds pose risks to reproductive health.

- Lithium: Incorporated in lasers, LEDs, circuit boards, and lithium-ion batteries; it contains toxic metals including cobalt, nickel, and manganese.

- Acids: Sulfuric and hydrochloric acids are utilized in the processing of circuit boards; they generate corrosive fumes that can lead to respiratory problems.

- Plastics: Present in circuit boards and cables; these materials are carcinogenic and may pose long-term health hazards.

- Brominated Flame Retardants (BFRs): Employed in circuit boards and PVC cables; during combustion, they release carcinogenic brominated dioxins and furans.

- Polychlorinated Biphenyls (PCBs) are employed in electrical transformers, capacitors, and serve as plasticizers in paints and plastics.

- Selenium is present in devices such as photoelectric cells, pigments, photocopiers, and fax machines.

- Silver is utilized in capacitors, switch contacts, batteries, and resistors.

- Cobalt is frequently used as an insulating material.

- Cathode Ray Tubes (CRTs) are commonly utilized in televisions and computer monitors. When these devices are disposed of improperly, they pose an environmental risk as hazardous materials such as cadmium, lead, barium, and nickel can leach into groundwater.

- Printed Circuit Boards (PCBs) and switches contain harmful substances including tin, lead, brominated dioxins, cadmium, and mercury. During activities such as desoldering or open burning, these toxic materials can be emitted into the air or released into waterways.

- Batteries come in various types, including those based on cadmium, lead, lithium, mercury, and nickel. Improper disposal of these batteries can result in soil and water contamination due to the release of toxic metals.

E-Waste Production and Recycling:

- In 2019, the global generation of electronic waste reached 53.6 million tons (mt), marking an increase of nearly 21 percent over a five-year period.

- According to a report from the United Nations University (UNU), it is projected that e-waste will rise by 38% during the decade from 2020 to 2030.

- Asia was the leading region in e-waste production in 2019, generating approximately 24.9 million tons, followed by the Americas with 13.1 million tons and Europe with 12 million tons.

- The majority of e-waste that year comprised small equipment (17.4 million tons), large equipment (13.1 million tons), and temperature exchange devices (10.8 million tons).

- Notably, less than 18 percent of the e-waste produced in 2019 was collected and recycled.

- A significant portion of this waste, which included valuable materials such as gold, silver, copper, and platinum—worth billions of dollars—was primarily discarded or incinerated instead of being processed for recovery and reuse.

India:

- The production of electronic waste (e-waste) is rising at a rate that surpasses that of plastic waste in India. India has become the third-largest e-waste producer globally, following China and the USA, generating 3.8 million metric tonnes (MMT) in FY24—a staggering 100% increase over the last decade.

- The states contributing the highest volumes of e-waste include Maharashtra, Tamil Nadu, Andhra Pradesh, Uttar Pradesh, West Bengal, Delhi, Karnataka, Gujarat, and Madhya Pradesh. Among urban areas, Mumbai leads in e-waste generation, followed by Delhi, Bengaluru, Chennai, and Kolkata.